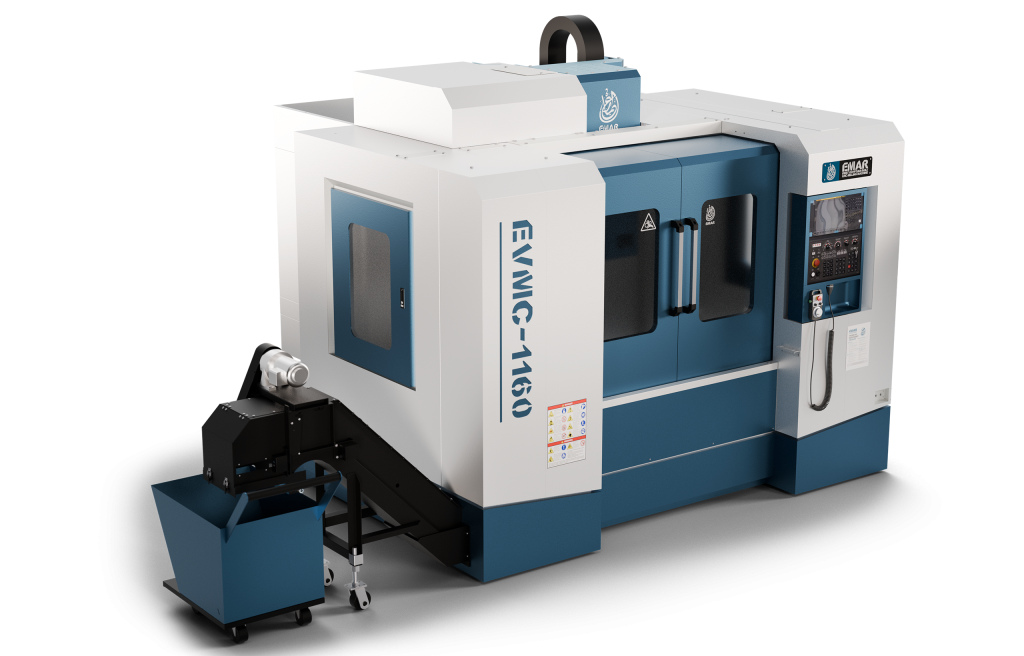

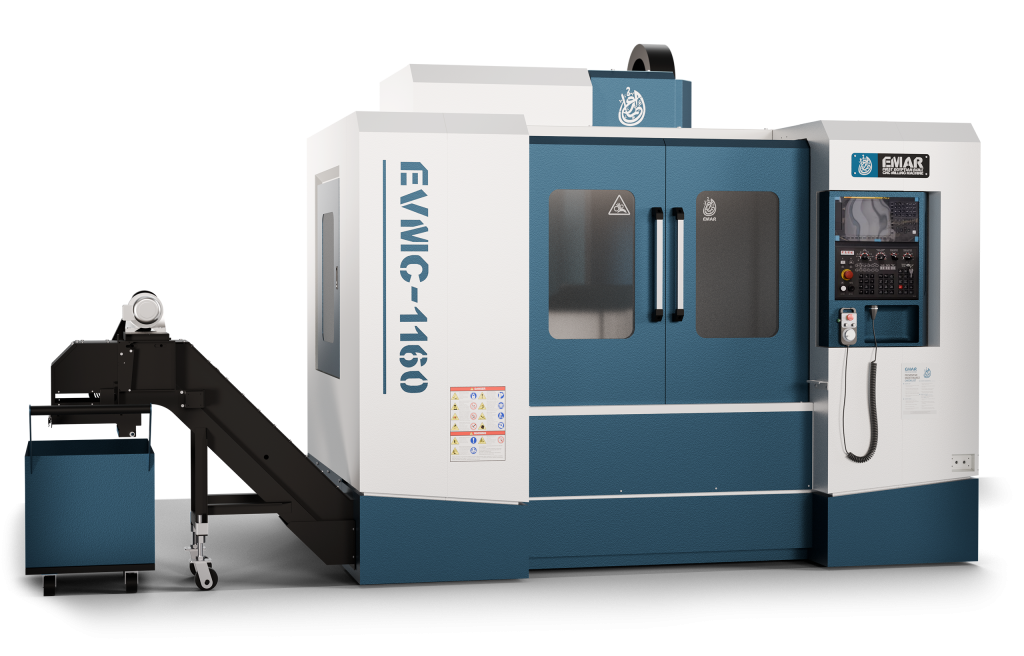

EVMC 1160 BT40 ATC

HEAVY WEIGHT VERTICAL MACHINE CENTER

IMPORTED

TAIWANESE DESIGN, TECHNOLOGY & QUALITY

CHINESE & EGYPTIAN ASSEMBLY, EFFICIENCY & FACILITY

EVMC 1160

HIGHLIGHTS

FANUC 0i MF Plus

Robust Control

CAST IRON CHASSIS

Optimum rigidity

Minimum noise and vibrations

HIGH-QUALITY COMPONENTS

Leading linear and

bearing components

4 AXIS SIMULTANEOUS

MACHINING

High-precision

4-axis rotary

BT40 OIL

COOLED SPINDLE

(11-15) kW 12k.RPM high-speed spindle

for precise results with optimum finish

DURABLE

AROUND THE CLOCK

Non-stop productivity

without compromising quality

EVMC 1160 BT40 ATC

HEAVY WEIGHT VERTICAL MACHINE CENTER

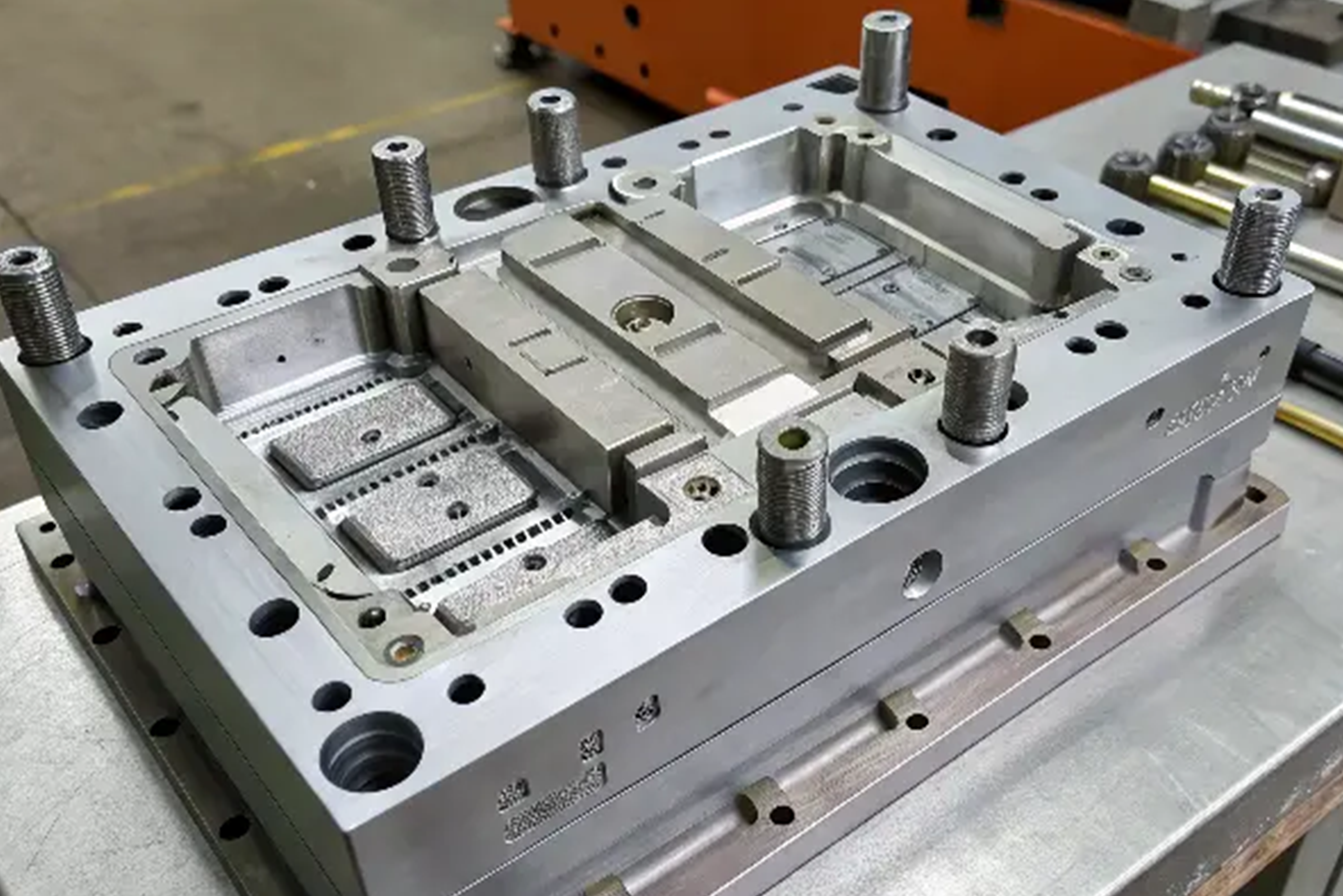

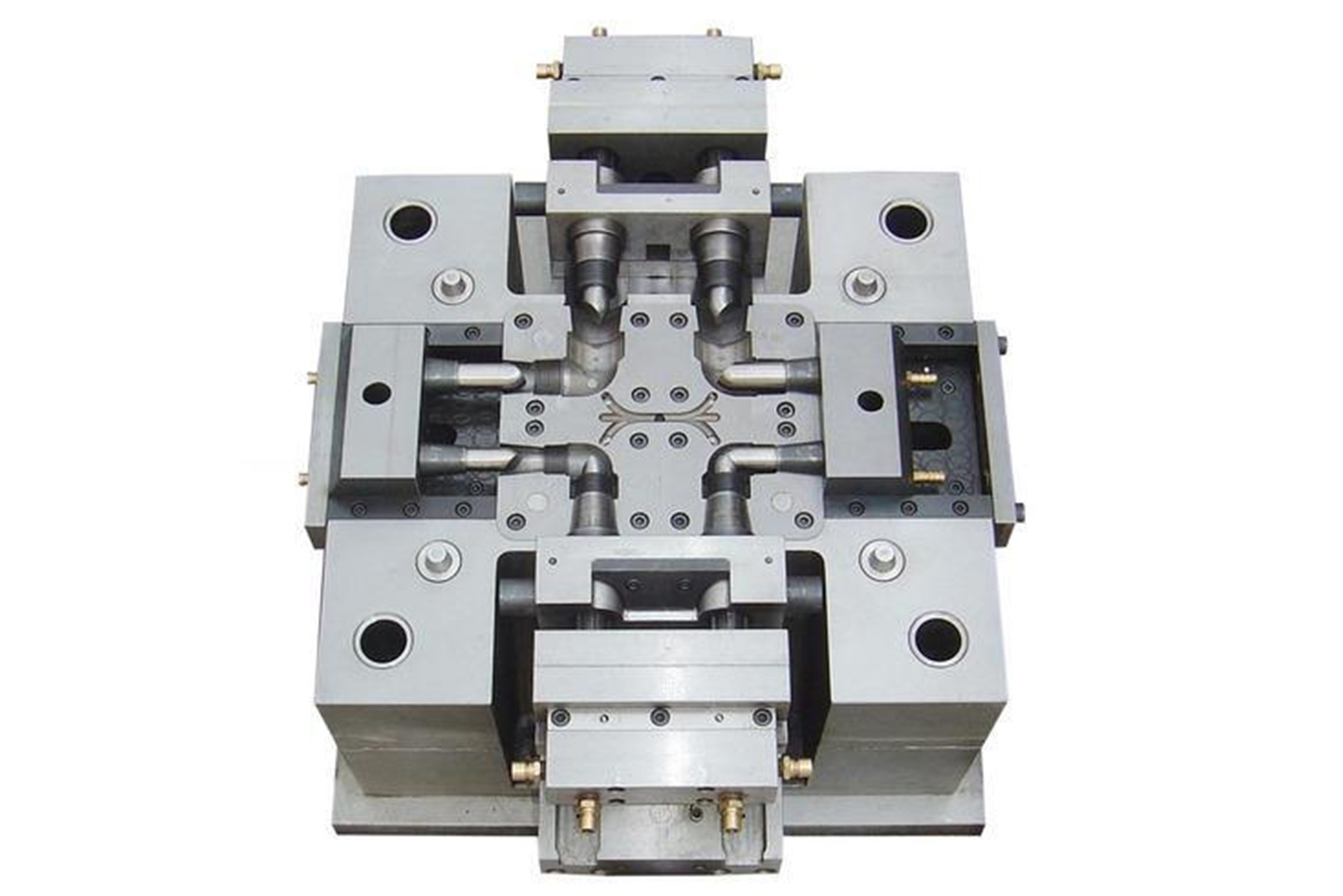

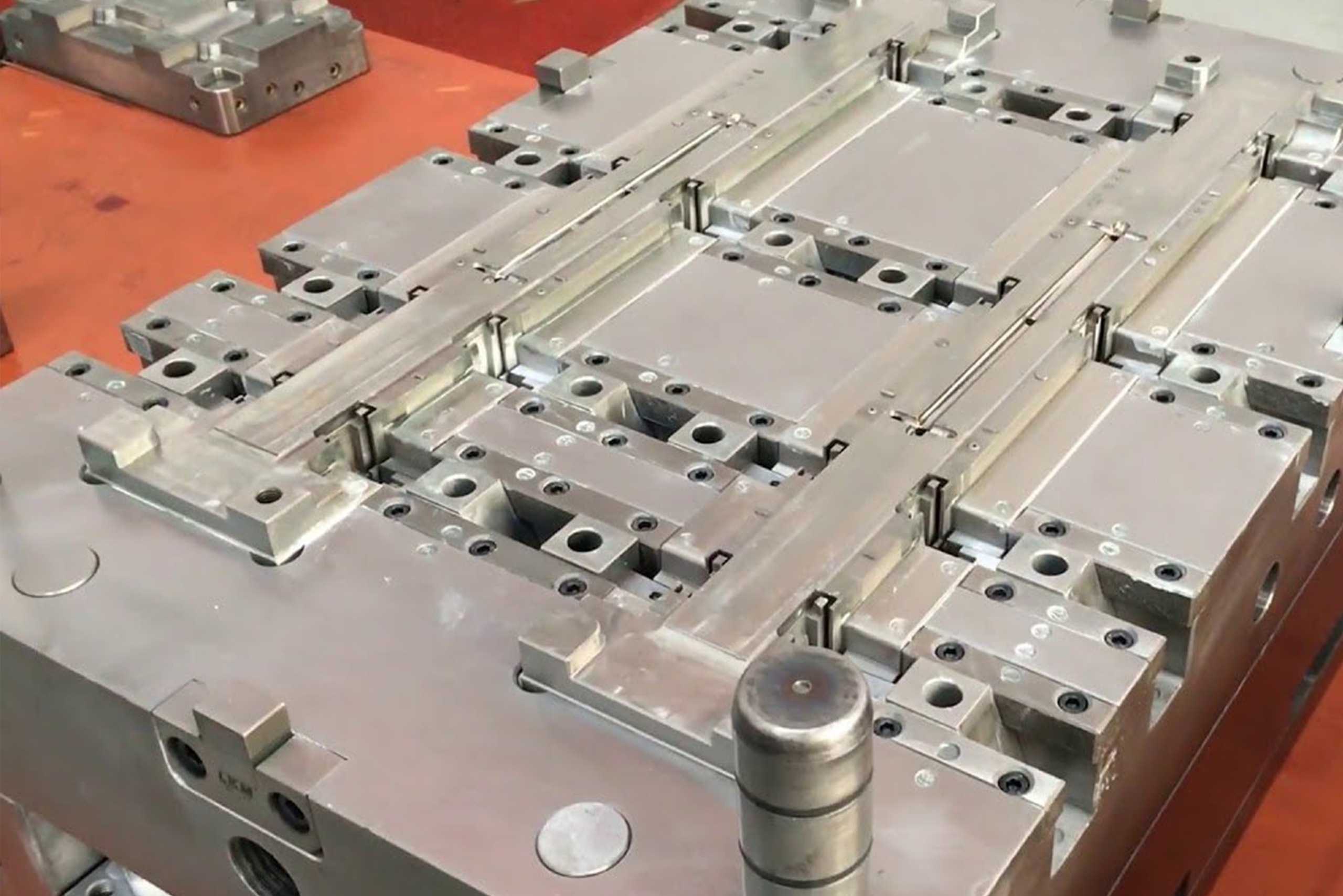

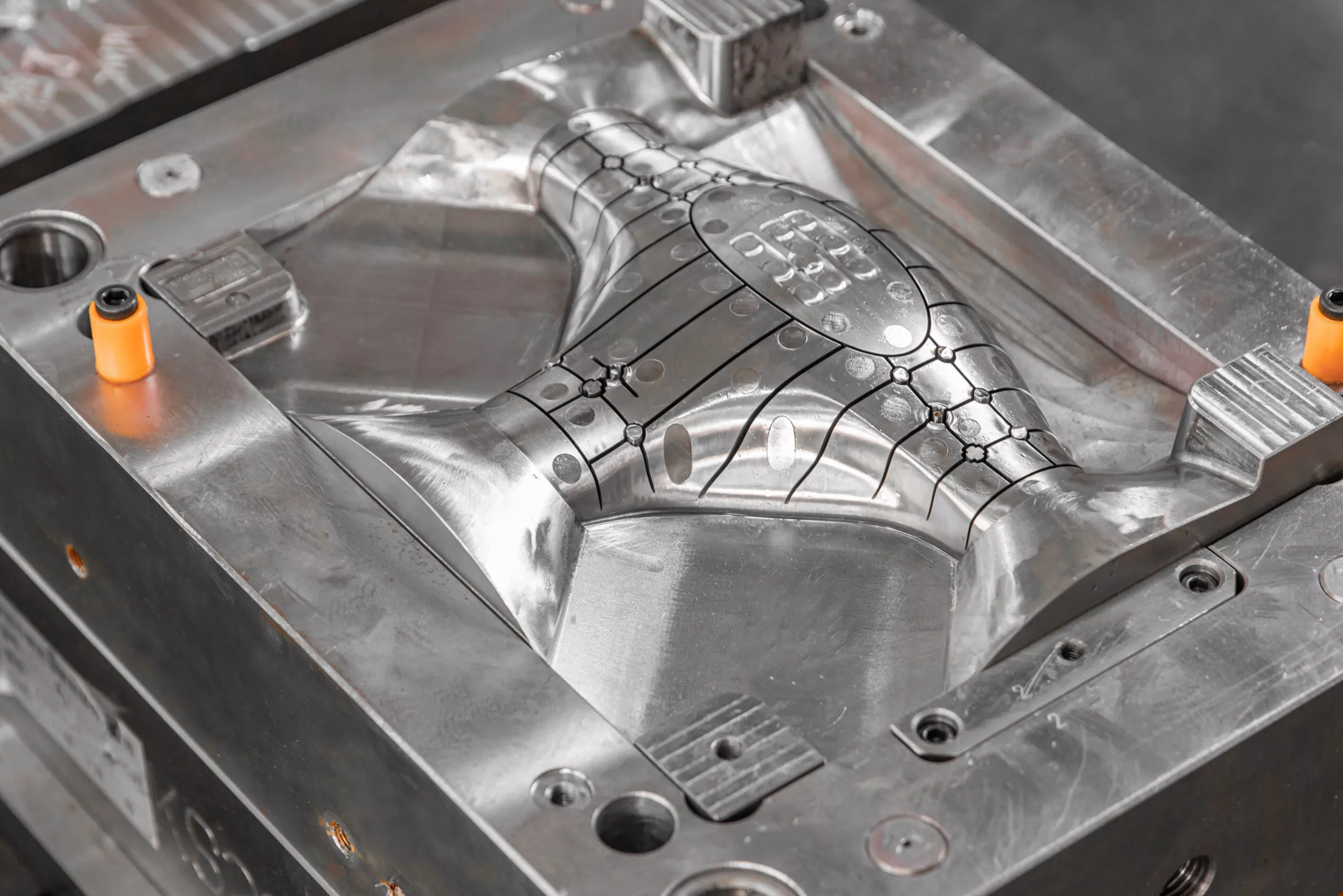

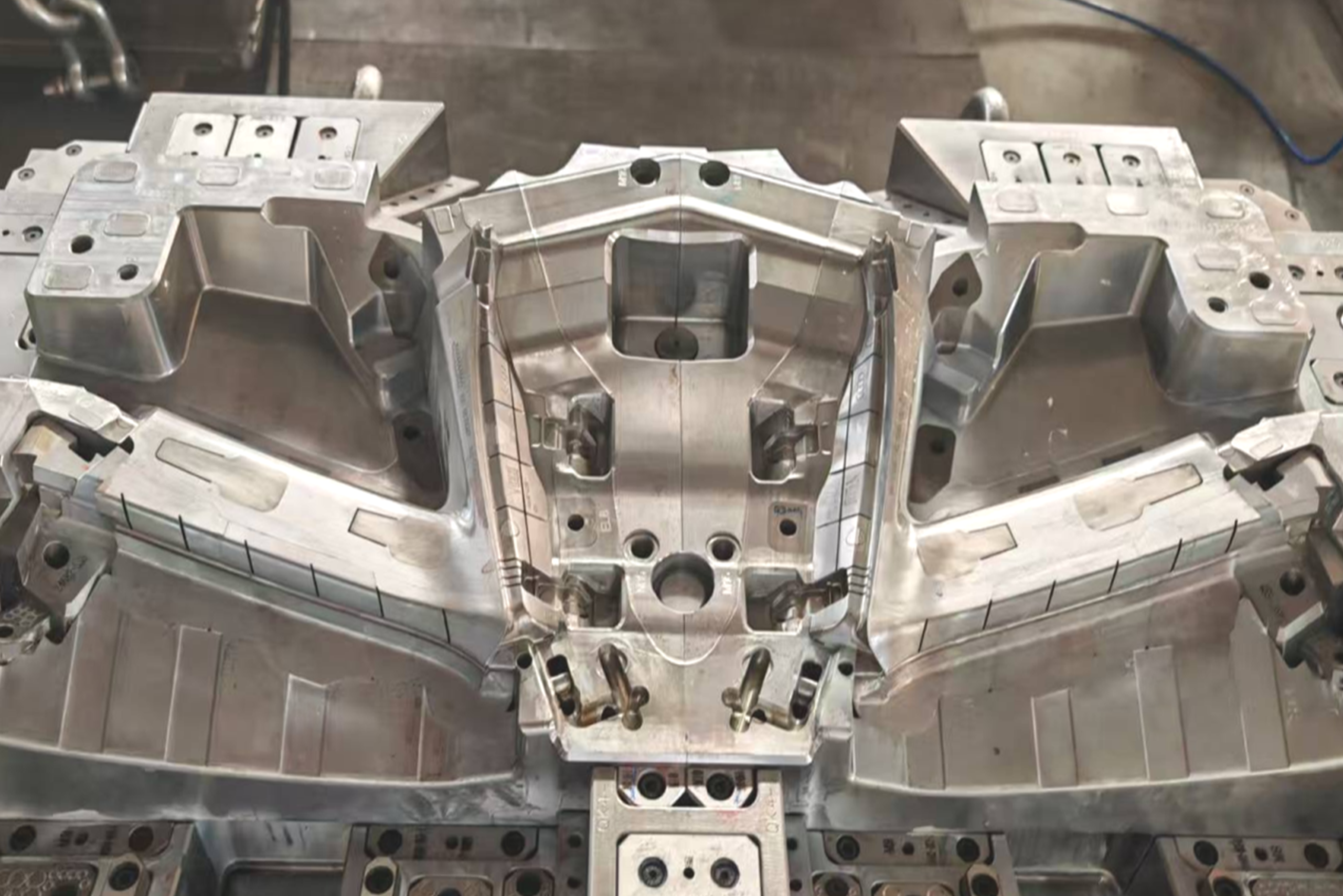

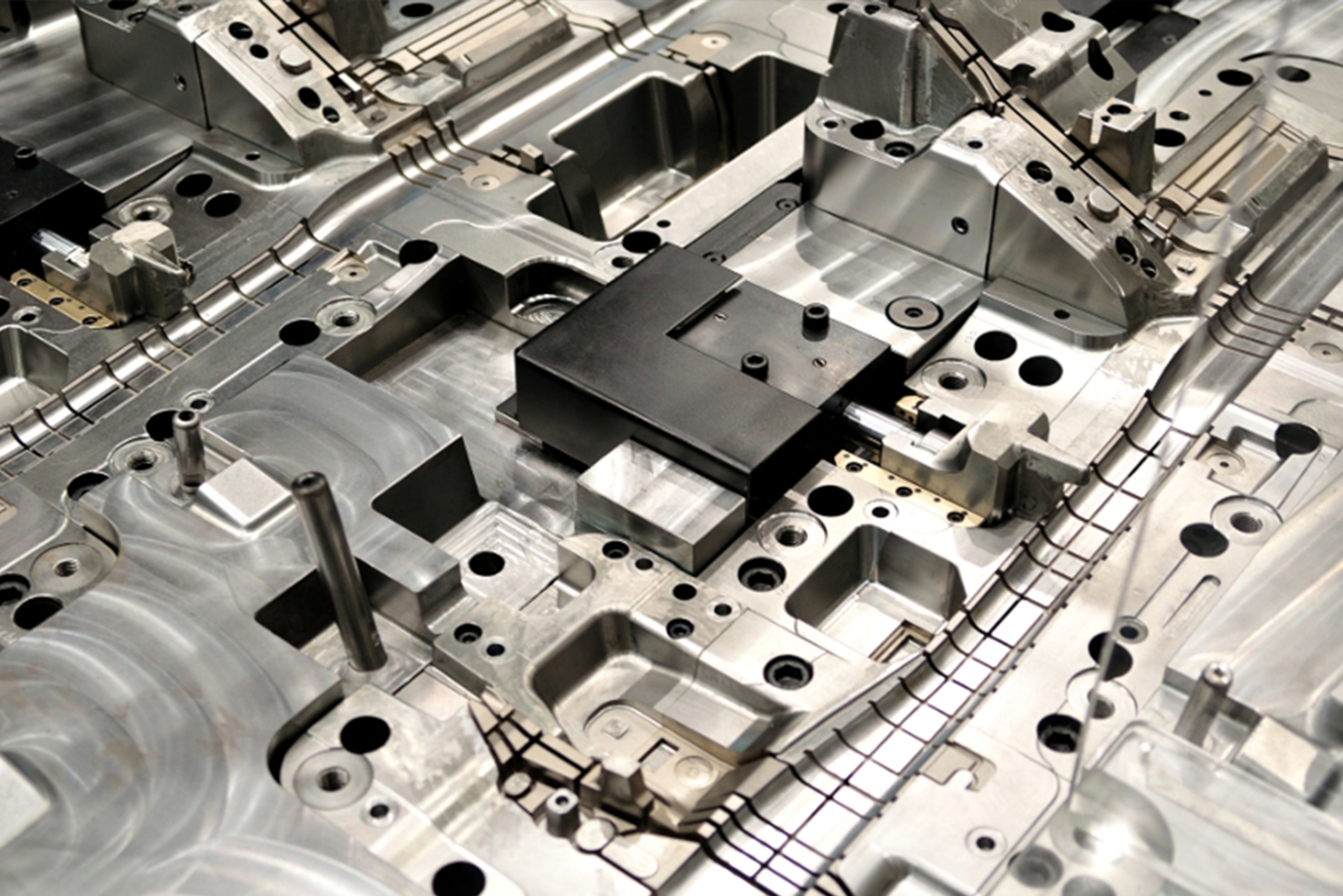

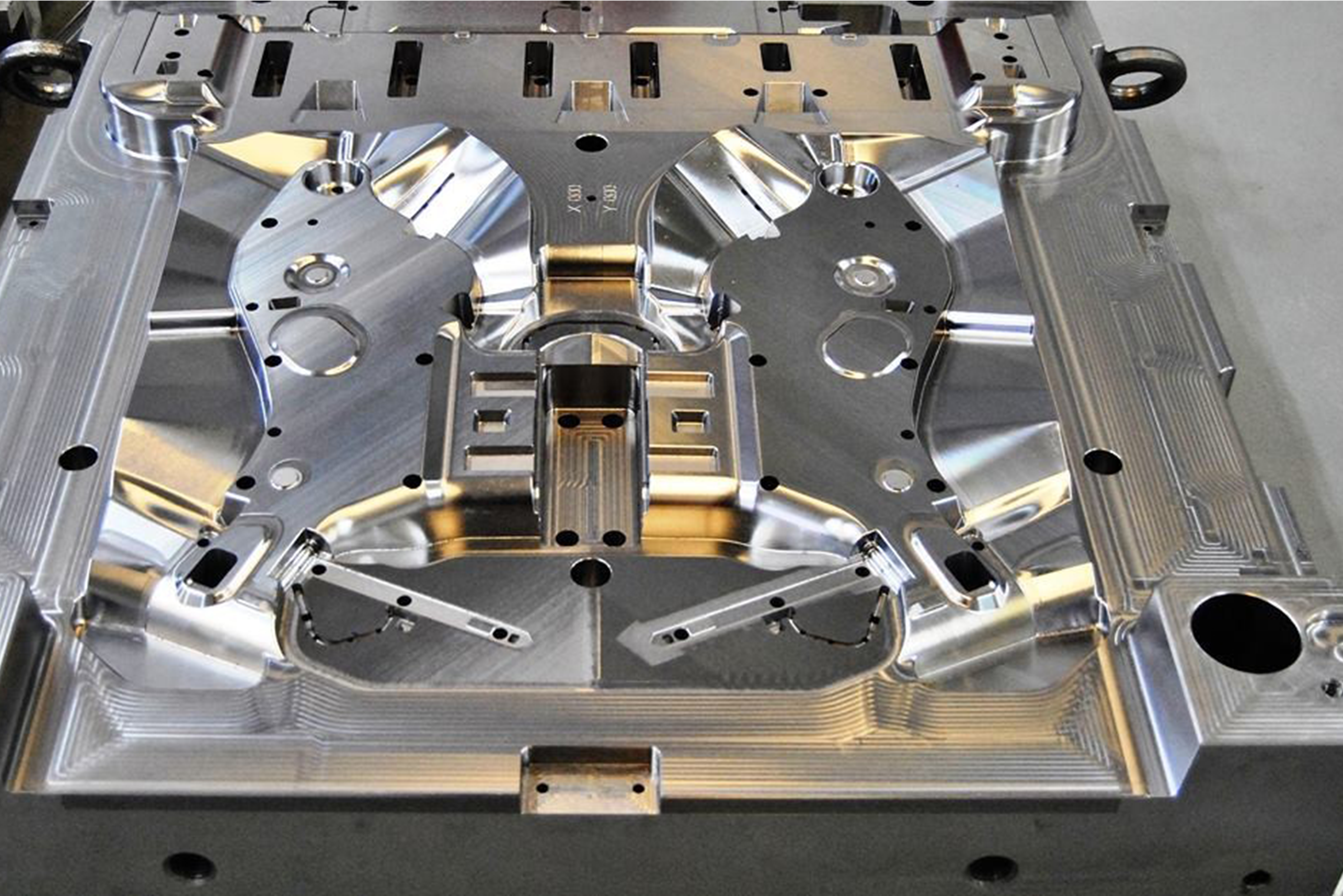

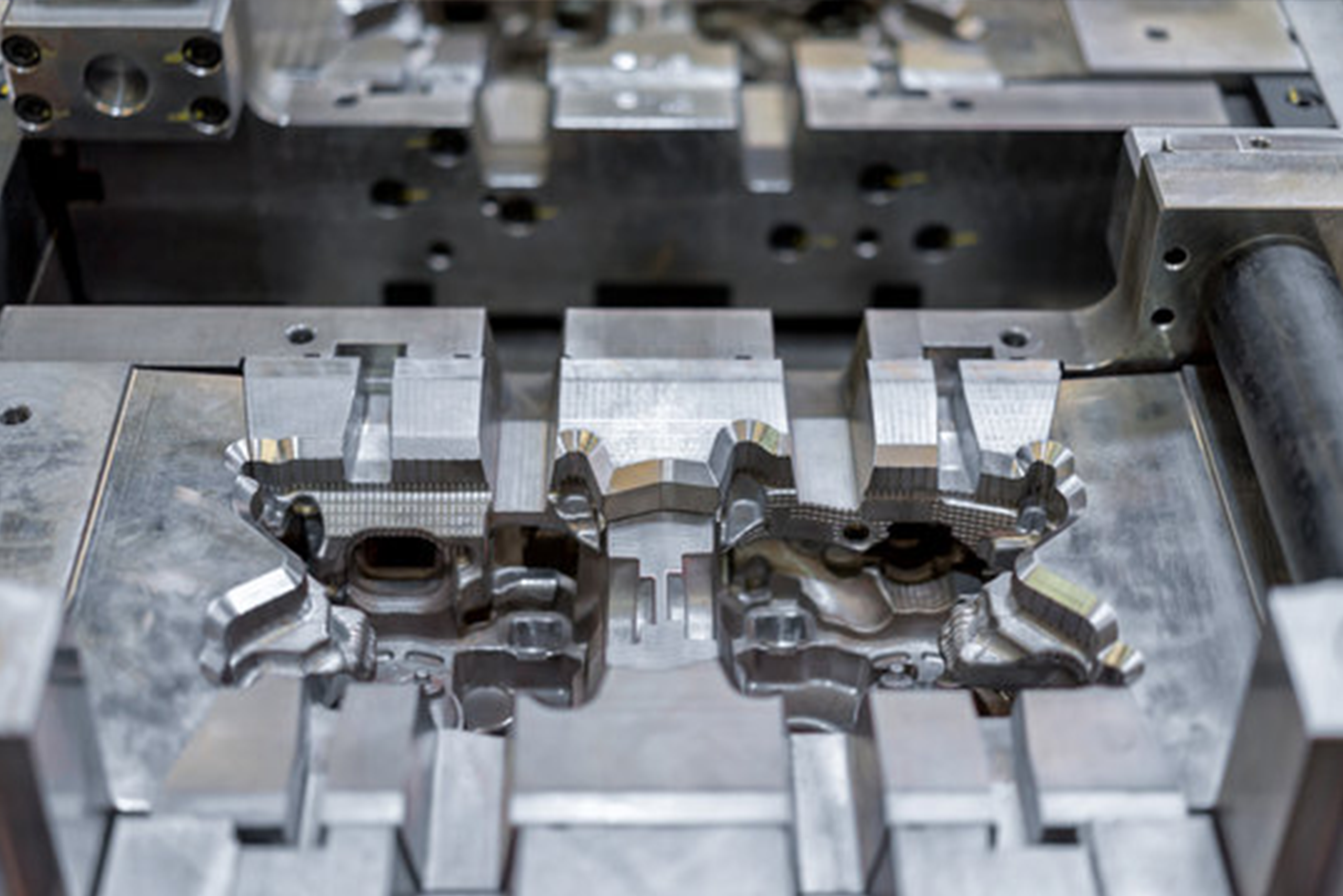

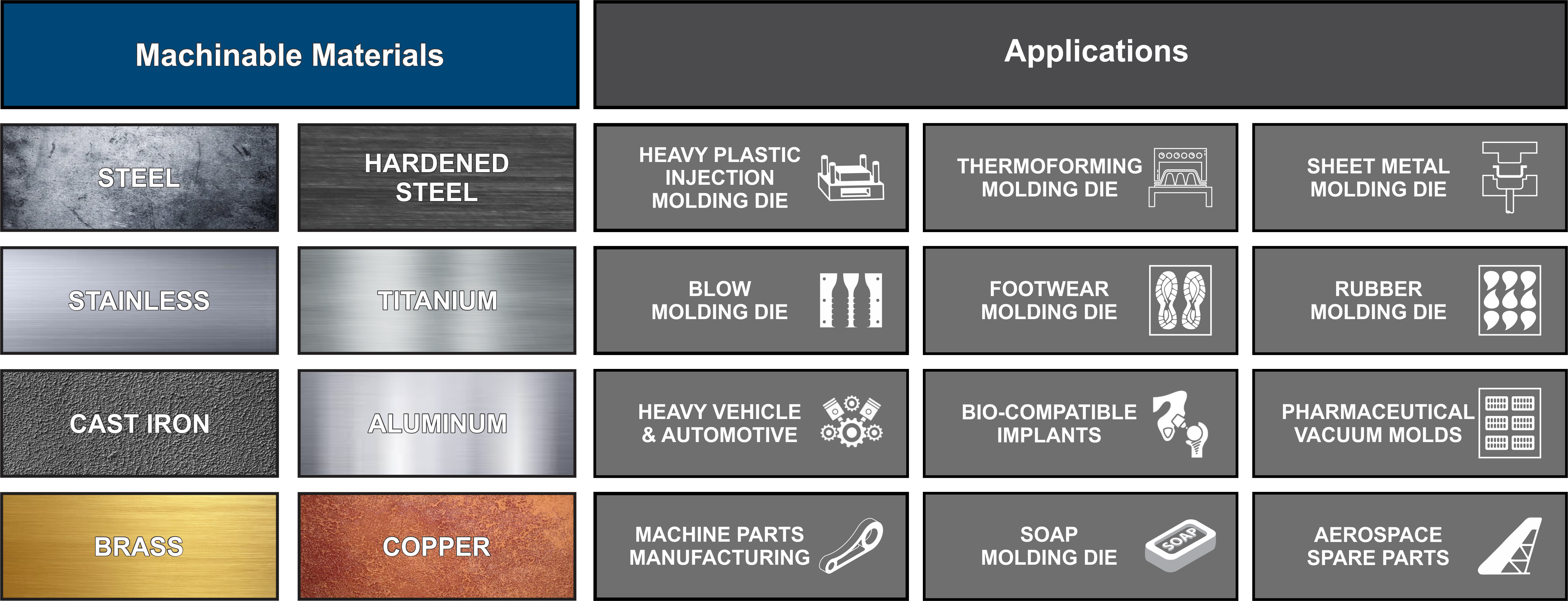

The VMC 1160 milling machine is a robust vertical machining center designed for heavy work in workshops and factories, enabling production of high-quality parts faster and with less effort.

-

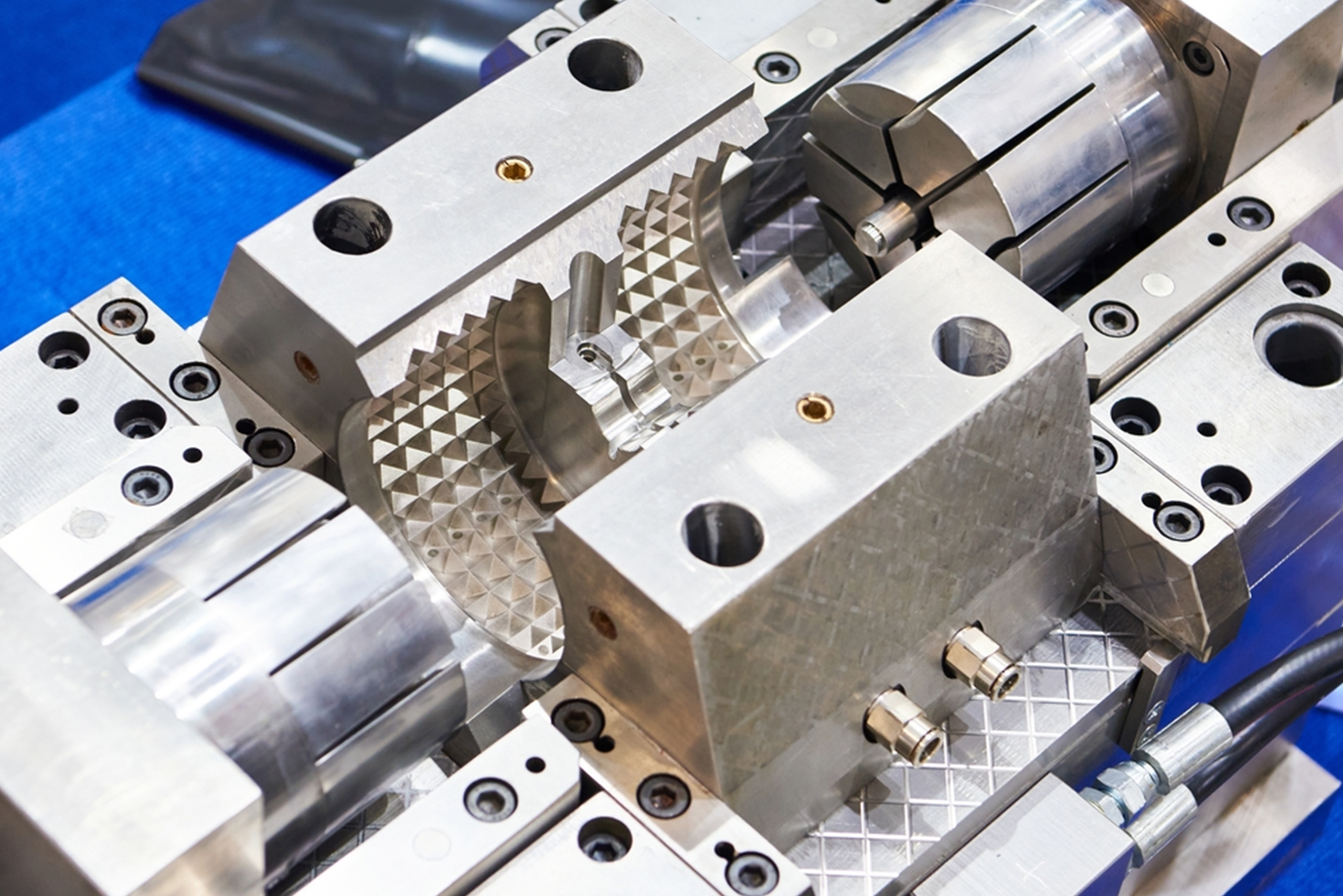

Wide motion range (3–4 axes) handle larger, more complex parts without constant repositioning, saving setup time and reducing errors.

-

Heavy-duty worktable ensures stability under heavy loads, fewer vibrations, longer machine life, and safer operation.

-

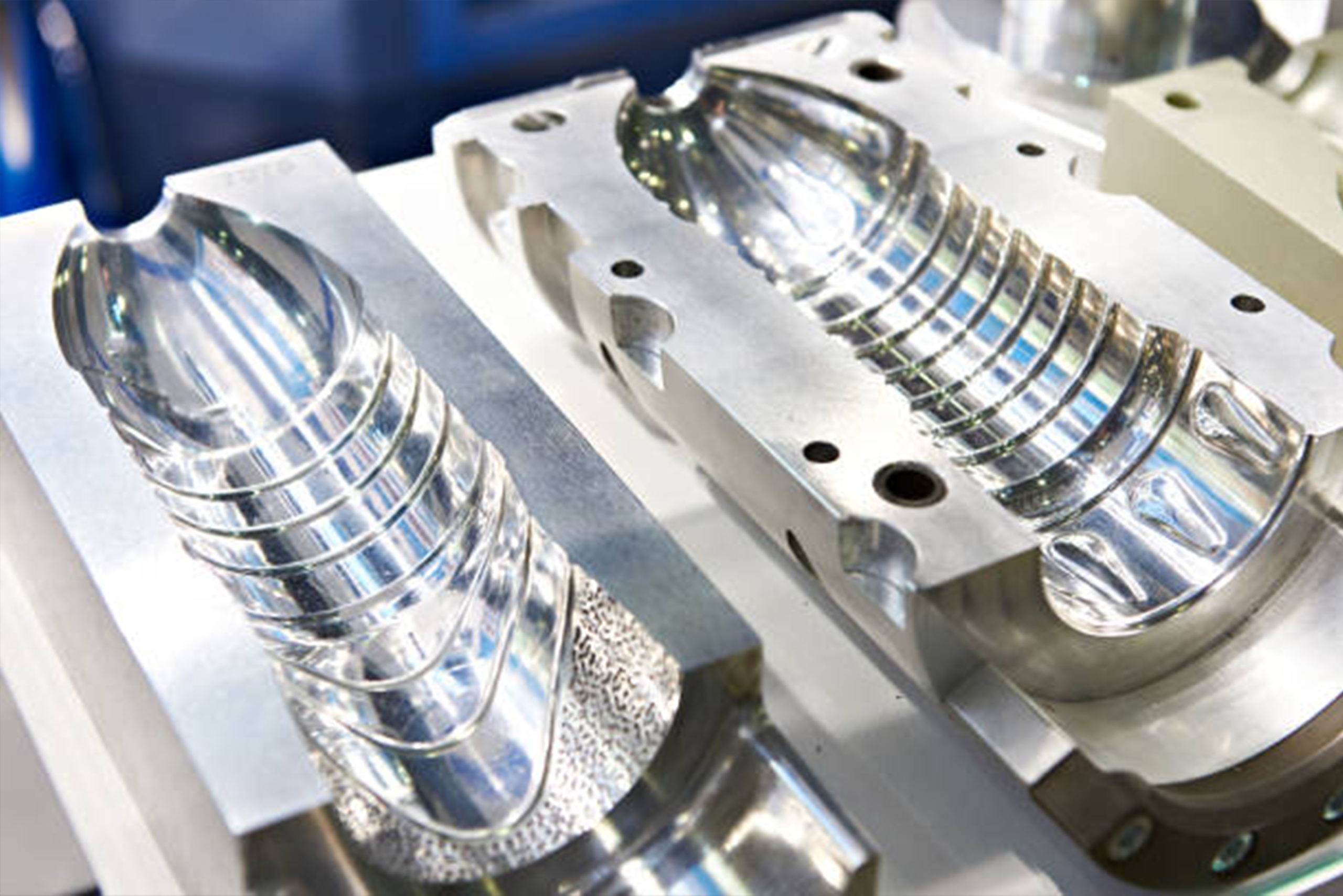

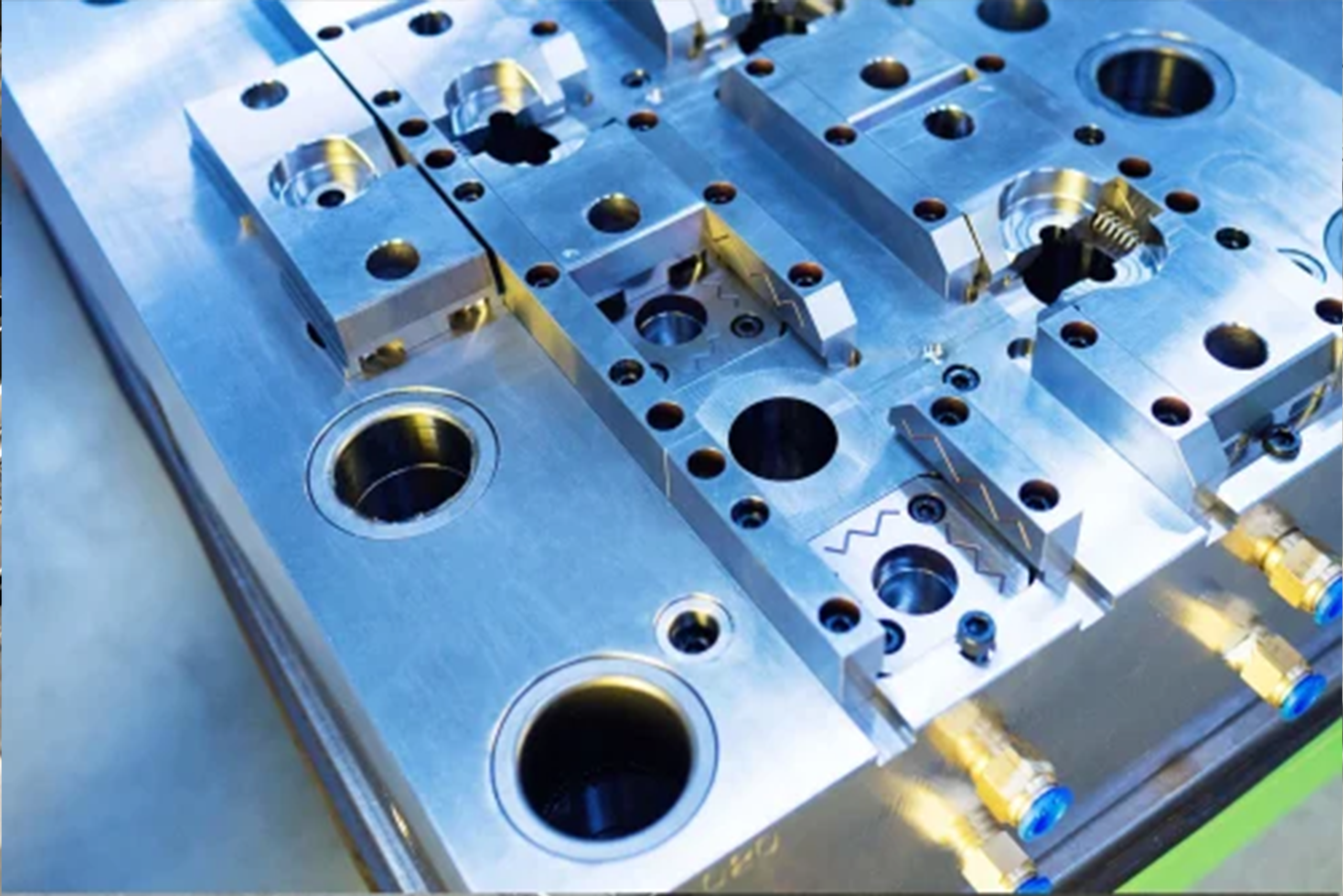

High-speed direct-drive spindle cuts through tough materials cleanly with smoother finishes, reducing polishing costs and boosting output.

-

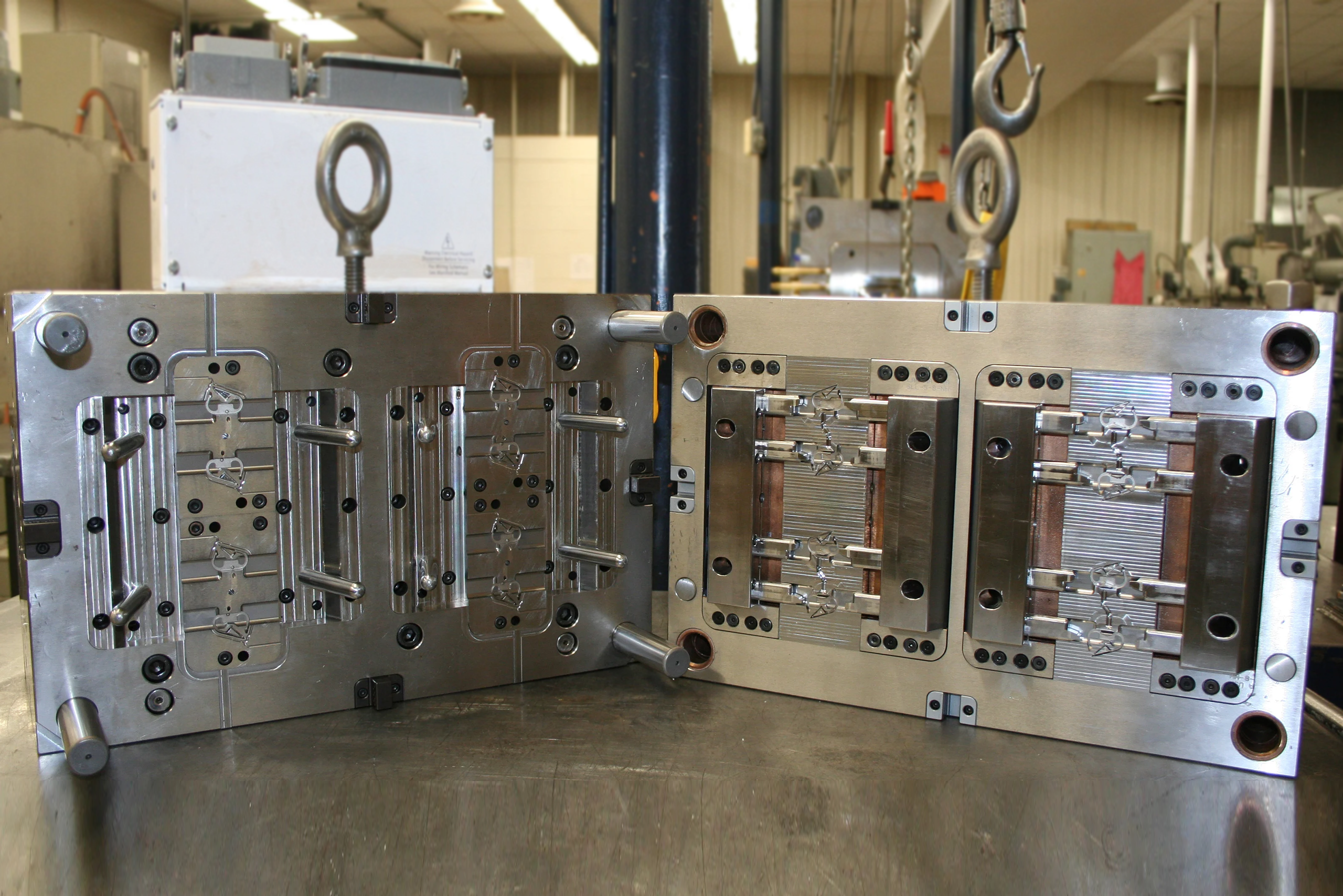

Disc-style tool magazine holds multiple tools with fast automatic changes to minimize downtime and maximize productivity.

- Premium components (Japanese control, Taiwanese linear guides & Spindle) reliable performance, less maintenance and long-term costs.

EVMC 1160 BT40 ATC

SPECIFICATIONS

|

Dimensions (W x D x H) |

2935x2880x2410 mm |

Operating system |

FANUC Oi MF Plus |

|

|

Table size |

1200 x 600 mm |

System configuration |

FANUC Japan |

|

|

Axis travel (X,Y,Z) |

1100 x 600 x 600 mm |

Guides and bearings |

HIWIN- SKF/NSK |

|

|

Spindle nose-table distance |

120 – 720mm |

X/Y/Z Ball Screw Diameter |

Ø 40 mm / 12 mm pitch |

|

|

Number of axes |

3 – 4 |

X/Y/Z Linear Size |

35/45/45 mm |

|

|

Spindle hole (7:24) |

BT40 |

X/Y/Z Axis rapid |

36/36/24 m/min |

|

|

Spindle motor power |

11 – 15 KW |

X/Y/Z Axis Motor Torque |

20/20/27 N.m |

|

|

Spindle speed |

12,000 rpm direct drive, oil chiller |

X/Y/Z Axis Motor Power |

Bis 3.0/3.0/3.0 KW |

|

|

Spindle type |

Okada |

Feed speed |

1-10,000 mm/min |

|

|

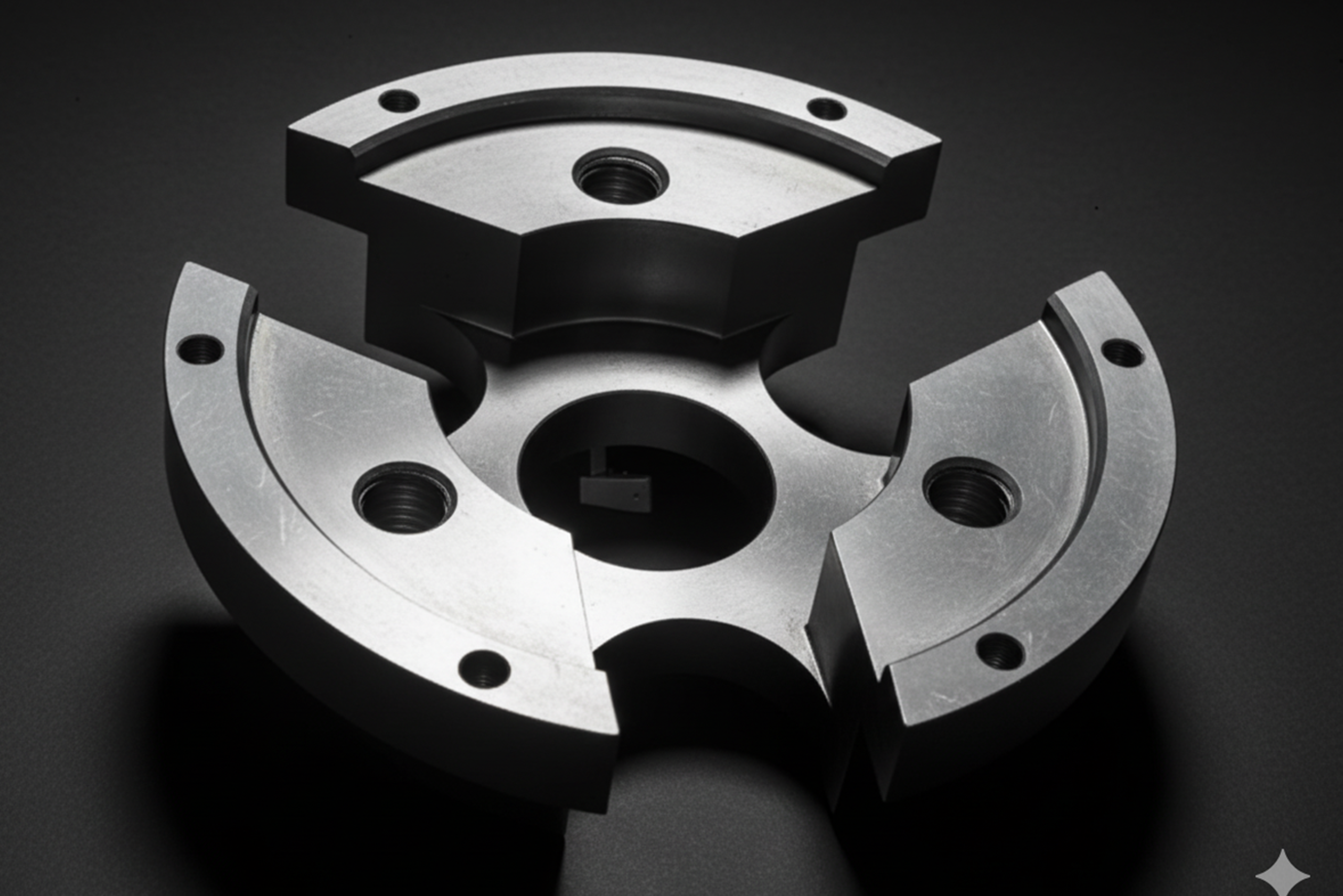

Tool magazine shape |

Disc |

Positioning accuracy / Repeat |

±0.005 / ±0.004 mm |

|

|

Tool magazine capacity |

24 |

Accuracy testing standards |

JIS |

|

|

Tool change time |

2.5 sec |

Weight |

6,500kg |

EMAR reserves the right to make changes to technical specs without prior notice