FIBER LASER CUTTING

FULL COVER EXCHANGE TABLE

IMPORTED

HIGH-END CHINESE QUALITY

FIBER LASER CUTTING

HIGHLIGHTS

CYPCUT CONTROL

User friendly

Integrated system

JAPANESE YASKAWA

SERVO DRIVERS

Faster & powerful Y-axis

with dual drivers

HIGH-QUALITY COMPONENTS

Leading linear and

bearing components

BOCI BLT

AUTO FOCUS

Focal distance

automatic follow-up

RAYCUS CE

LASER SOURCE

BEST ON THE MARKET

1,500 ~ 40,000 kW

DURABLE

AROUND THE CLOCK

Non-stop productivity

without compromising quality

FIBERLASER CUTTING

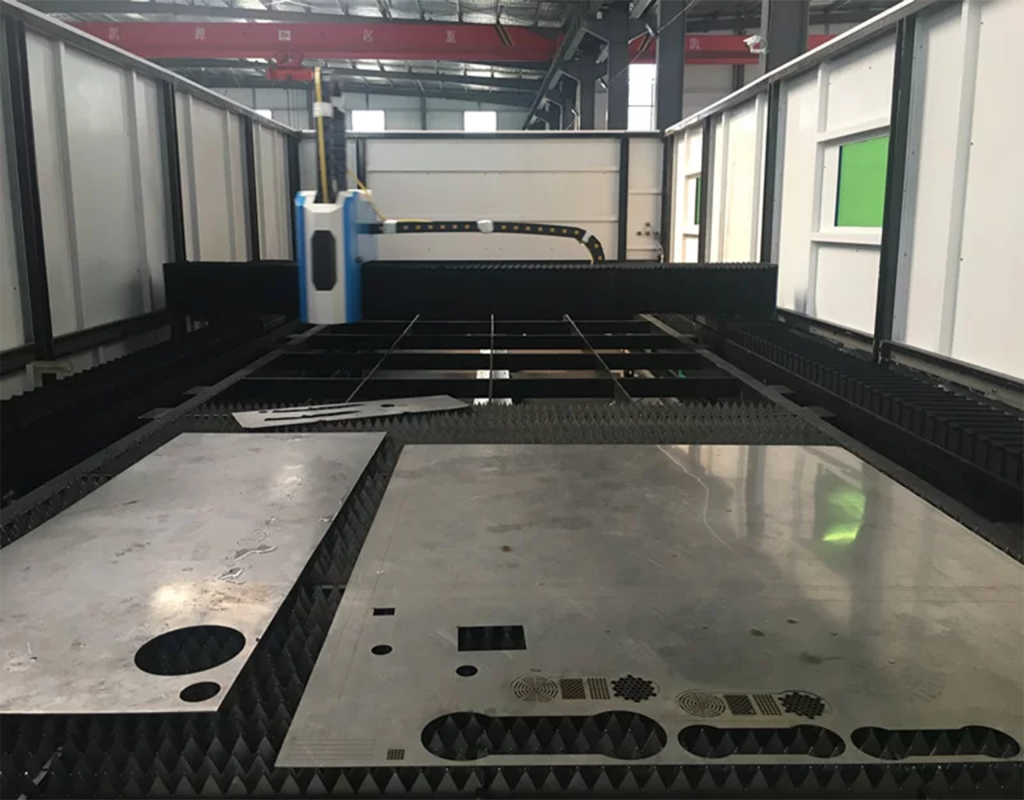

FULL COVER EXCHANGE TABLE

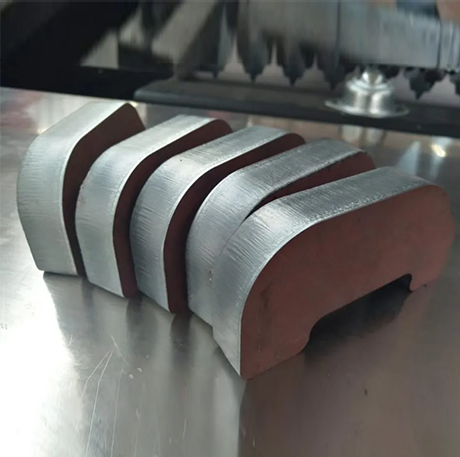

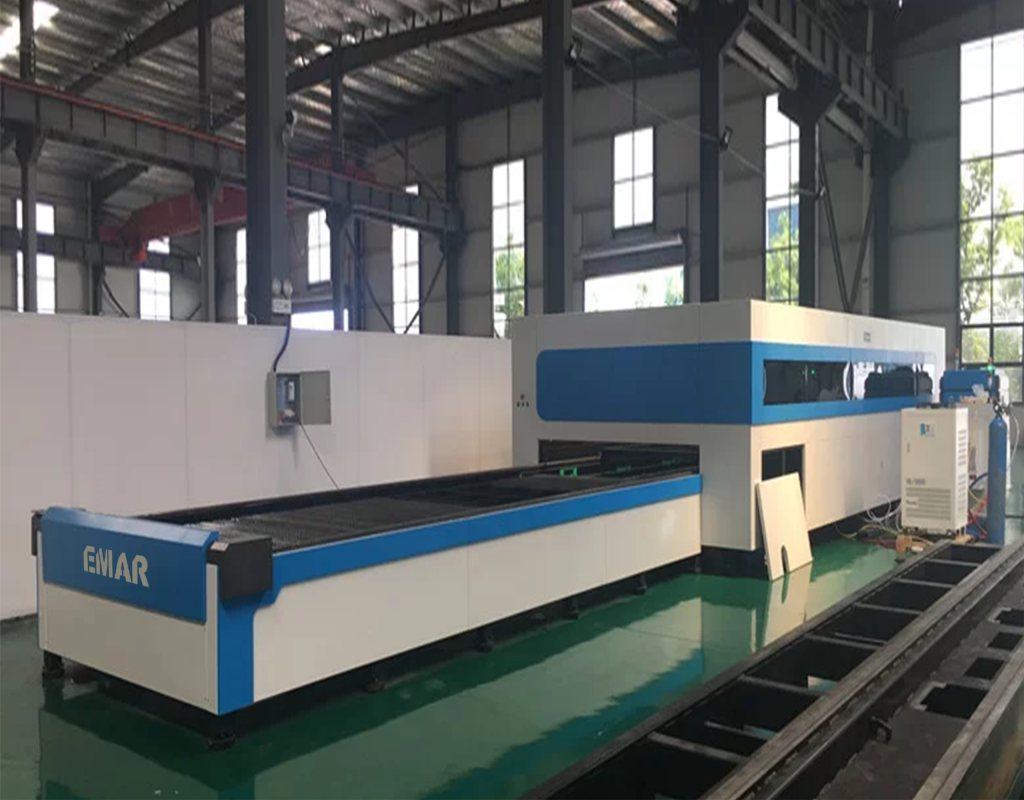

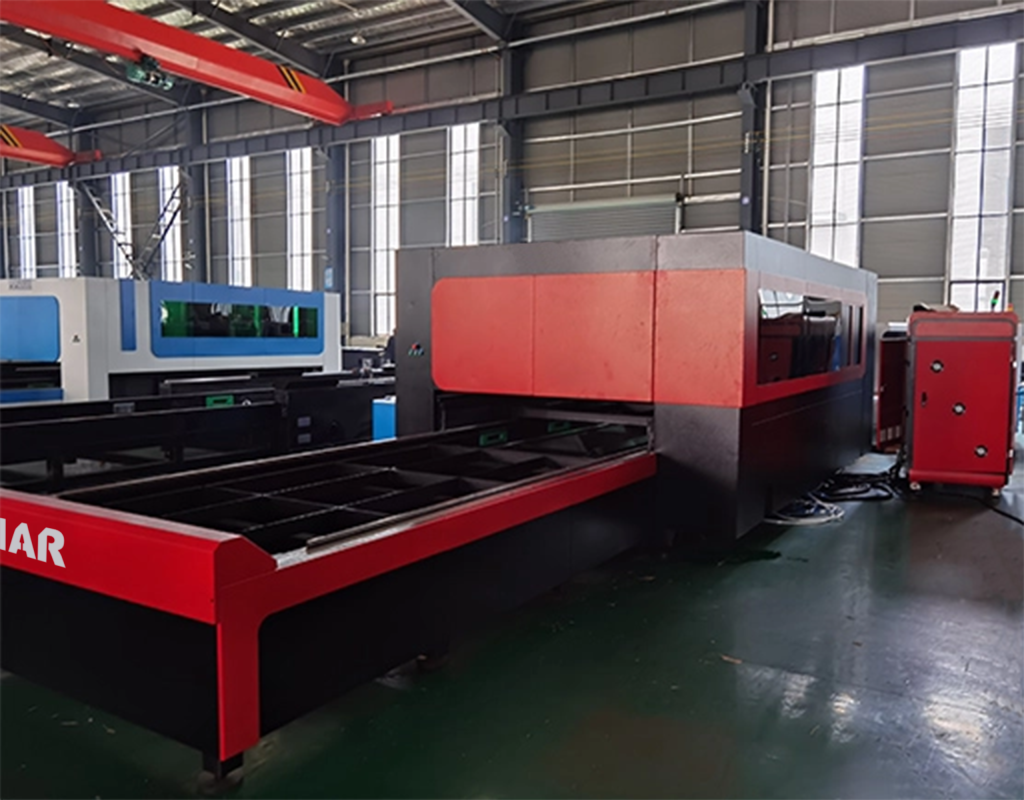

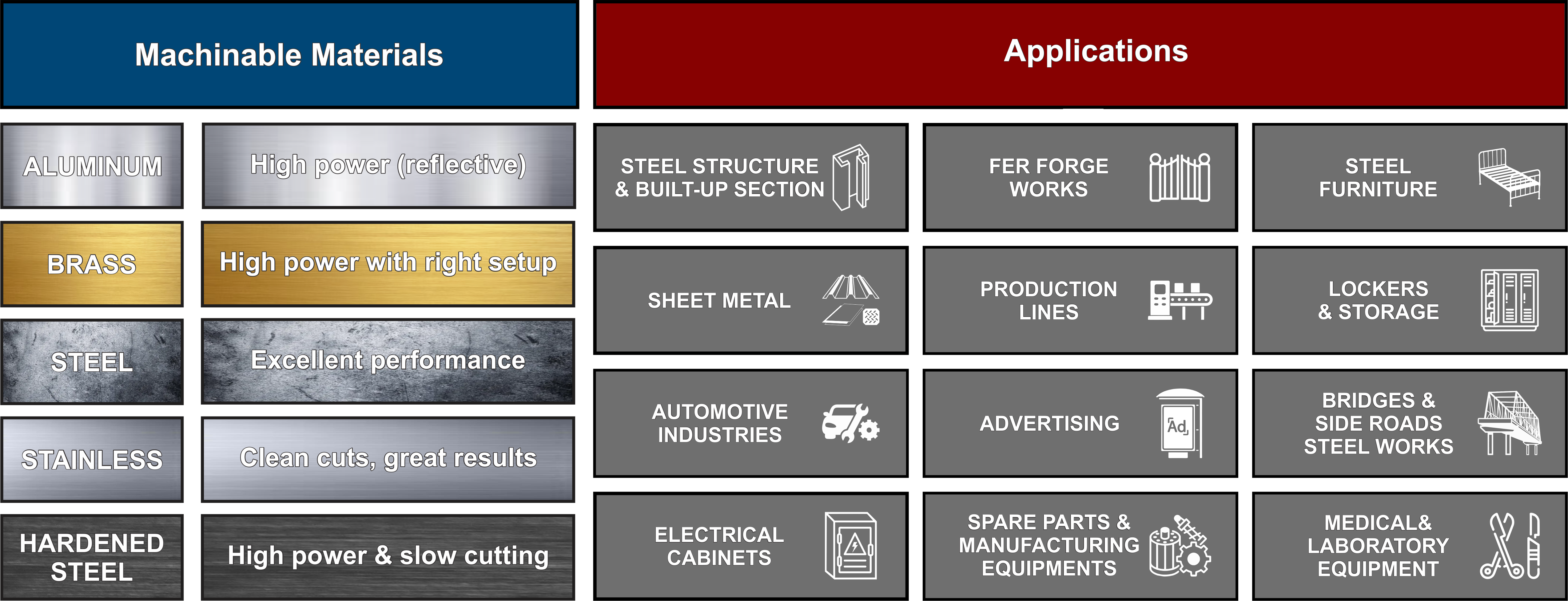

Built for speed, safety, and precision, this Full Cover Exchange Bed Machine delivers powerful performance for high-volume metal fabrication.

-

Raycus CE Fiber Laser Source provides clean, high-speed cuts across a wide range of metals with exceptional performance.

-

Full Enclosure Design enhances operator safety, improves dust and smoke containment, and supports compliance with industrial safety standards.

-

Auto Exchange Table system significantly reduces loading and unloading time, boosting productivity and enabling continuous, high-efficiency cutting.

-

Cypcut Control System offers intuitive operation with real-time monitoring, and intelligent path optimization for minimal material waste.

-

Dual Yaskawa Servo Motors with Shimpo Precision Reducers ensure fast, stable motion and repeatable cutting accuracy.

-

German ROR/YYC Gears and Taiwan HIWIN Square Guide Rails guarantee smooth, high-precision movement with long service life.

-

Auto-focus BOCI Laser Head adjusts automatically to varying material thicknesses, maintaining optimal cutting quality without manual intervention.

-

Integrated Cast Aluminum Beam balances lightweight design with high structural rigidity for consistent, high-speed performance.

-

Premium Components from Japan SMC / Airtac Pneumatics and France Schneider Electronics deliver reliable, responsive machine control.

-

30KVA Voltage Stabilizer protects sensitive electronics and ensures consistent machine performance in fluctuating power conditions.

-

Advanced Smoke Purification System and Hanli Water Cooling Unit maintain a clean working environment and stable laser operation.

CNC FIBER LASER CUTTING MACHINE

SPECIFICATIONS

|

Laser Power |

3,000 – 40,000 kW |

Laser type |

Raycus CE / IPG |

|

|

|

|

Control system |

FSCUT – Cypcut / Hypcut |

|

|

Working size (customized) |

1500 x 3000 mm 2000 x 4000 mm |

Guides and bearings |

HIWIN square rail |

|

|

1500 x (6000/8000/12000) mm 2000 x (6000/8000/12000) mm |

Gears |

Germany ROR/YYC |

||

|

2500 x (6000/8000/12000) mm 3000 x (6000/8000/12000) mm |

Max. cutting speed (considering laser power) |

0-80m/min (considering material and thickness) |

||

| Platform type | Full cover / Exchange bed |

X/Y/Z Axis operation precision |

≤±0.05mm/m |

|

|

Water cooler |

Hanli |

X/Y/Z Axis repeat precision |

≤±0.03mm /m |

|

|

Gantry beam |

Integrated cast Aluminum |

Min. line width |

≤0.15mm |

|

|

Laser head |

BOCI auto focus |

Max. running speed |

120m/min |

|

|

Reducer |

Shimpo |

Drivers system |

Japanese Yaskawa servo motors |

|

|

Electronic parts |

French Schneider |

Transmission way Y/X-Axis |

Double driver gear rack / ball screw |

|

|

Pneumatic parts |

Japan SMC /Airtac |

Power requirements |

380 V / 50 Hz adjustable |

EMAR reserves the right to make changes to technical specs without prior notice