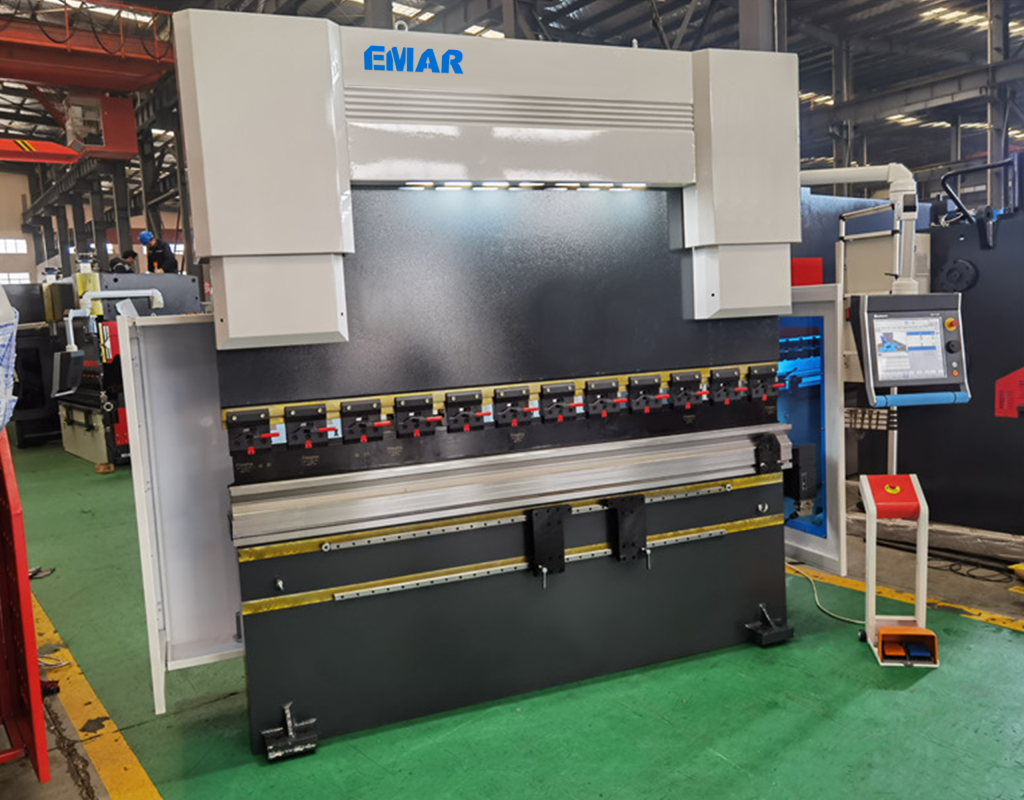

PRESS BRAKE CNC MACHINE

OIL-ELECTRIC HYBRID

IMPORTED

HIGH-END CHINESE QUALITY

PRESS BRAKES

HIGHLIGHTS

DELEM CONTROL

User friendly

Integrated system

OIL-ELECTRIC

HYBRID MACHINE

Higher accuracy

More efficient

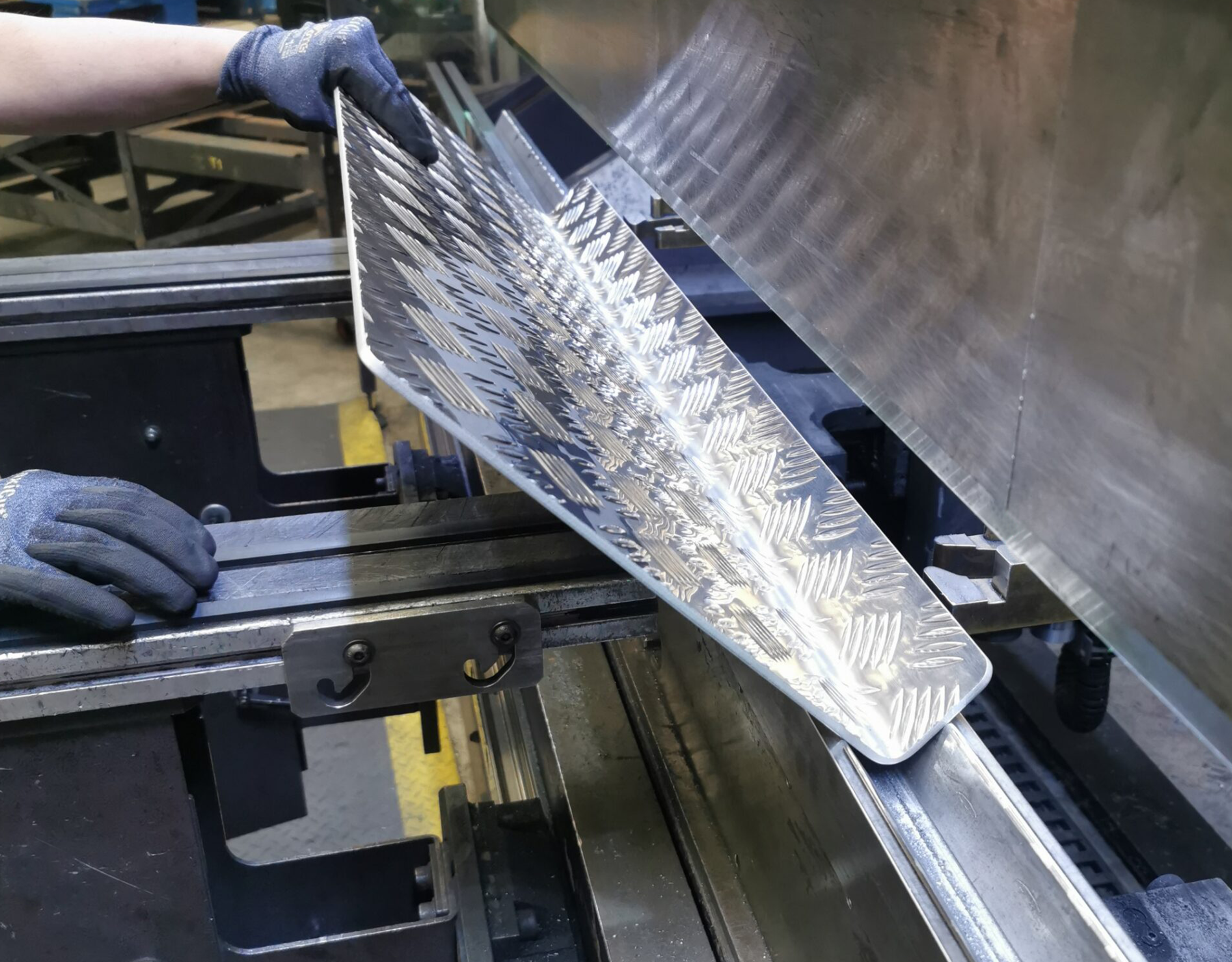

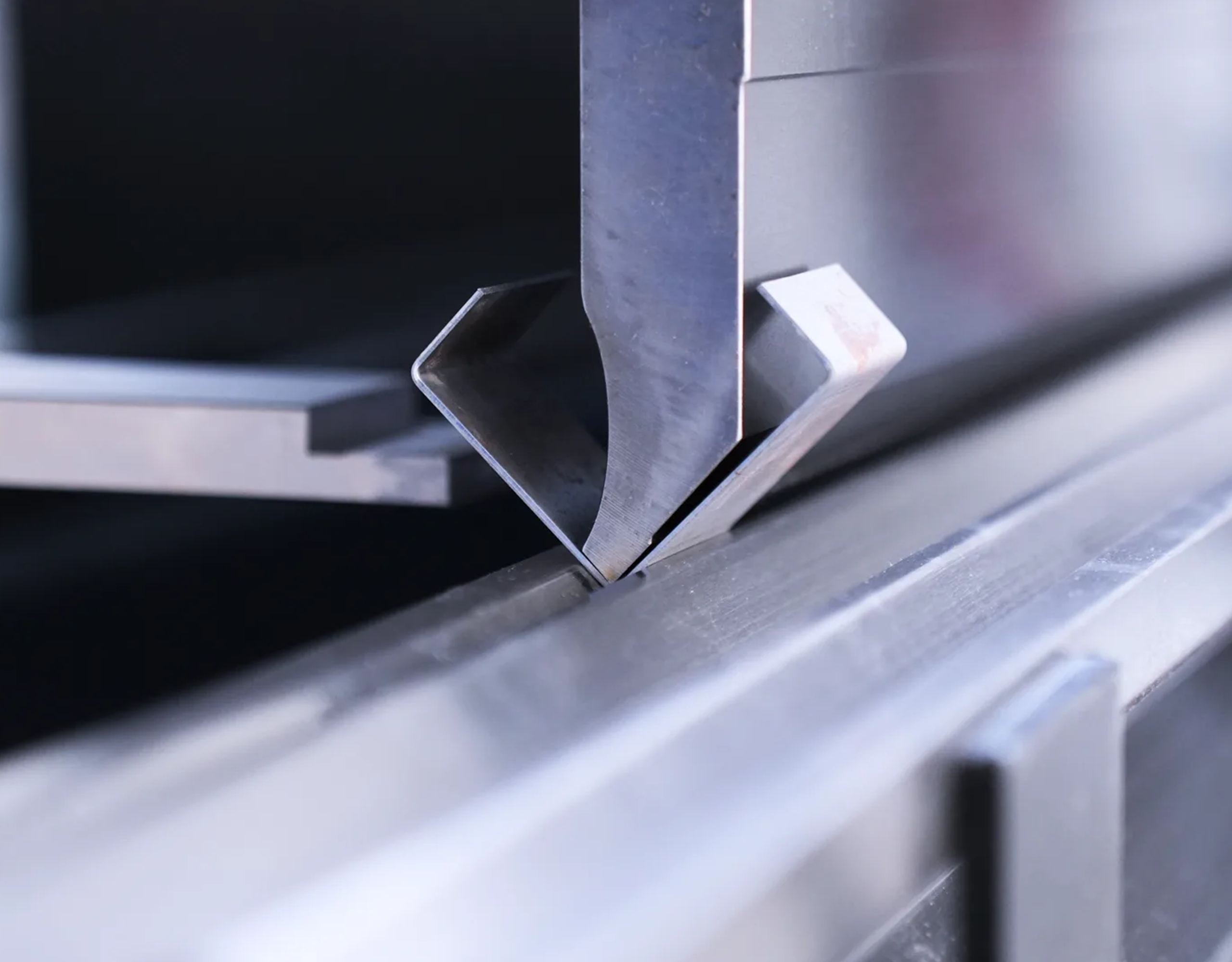

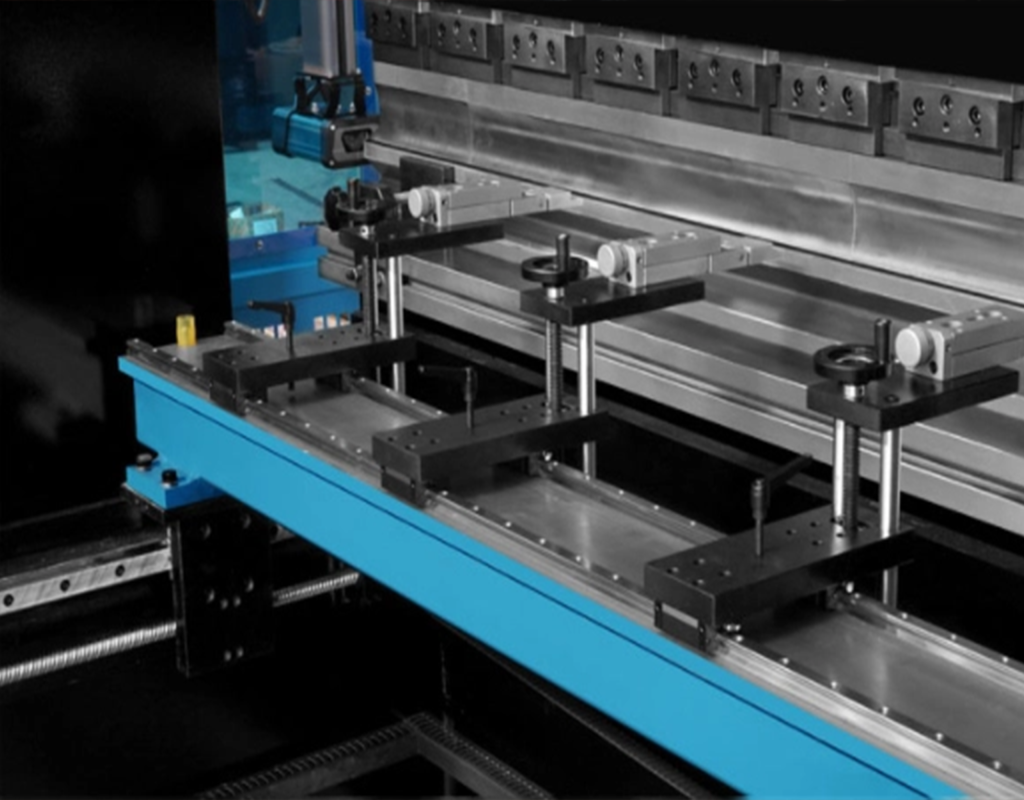

FRONT SUPPORTS

& FAST CLAMPS

Optimum productivity

with no hassle

LASER OPTICAL

SAFETY GUARDS

Optical protection

Maximum safety

ANGLE MEASURING

SYSTEM

Laser-beams & cameras

Accurate & consistent

DURABLE

AROUND THE CLOCK

Non-stop productivity

without compromising quality

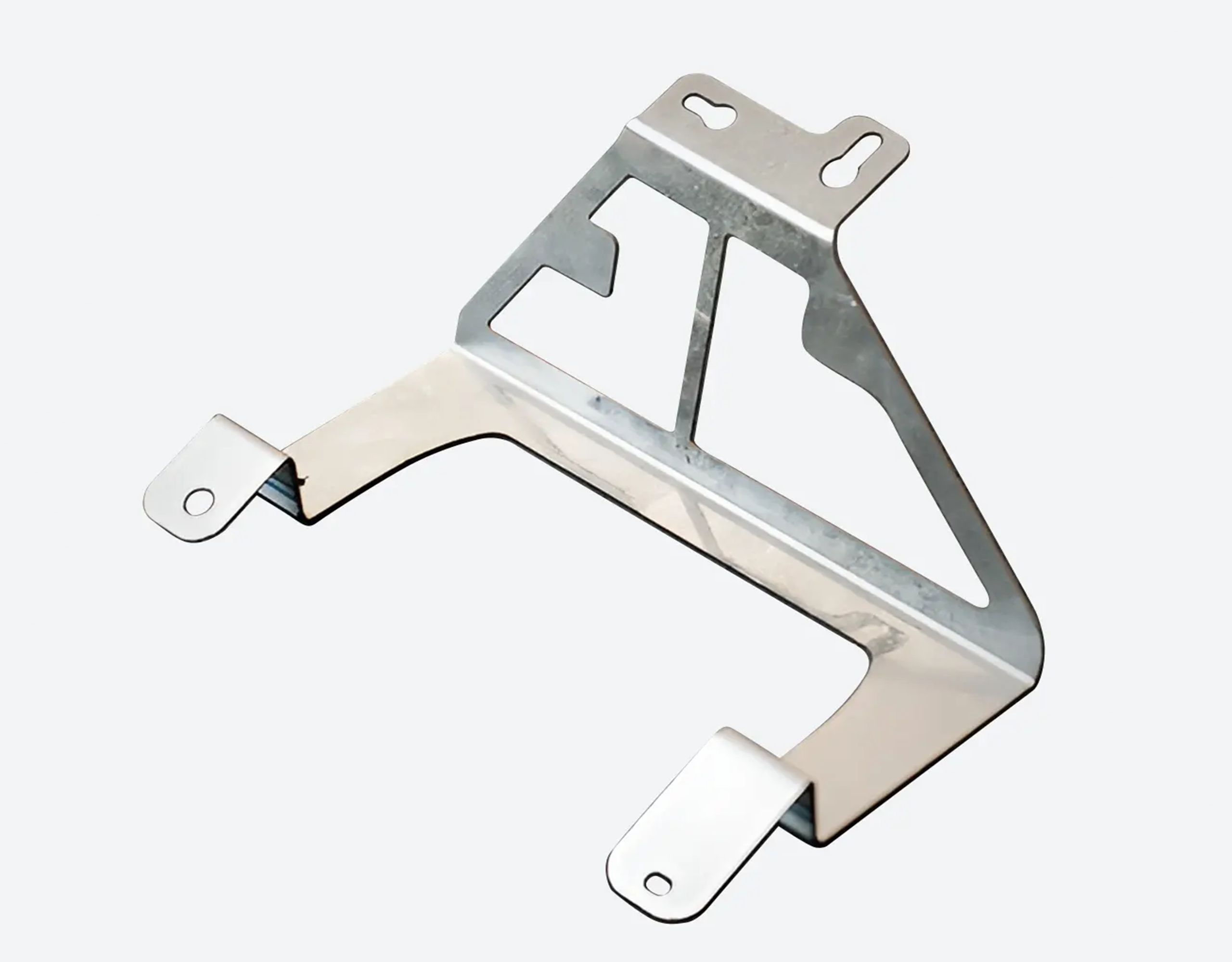

CNC PRESS BRAKE MACHINES

OIL-ELECTRIC HYBRID

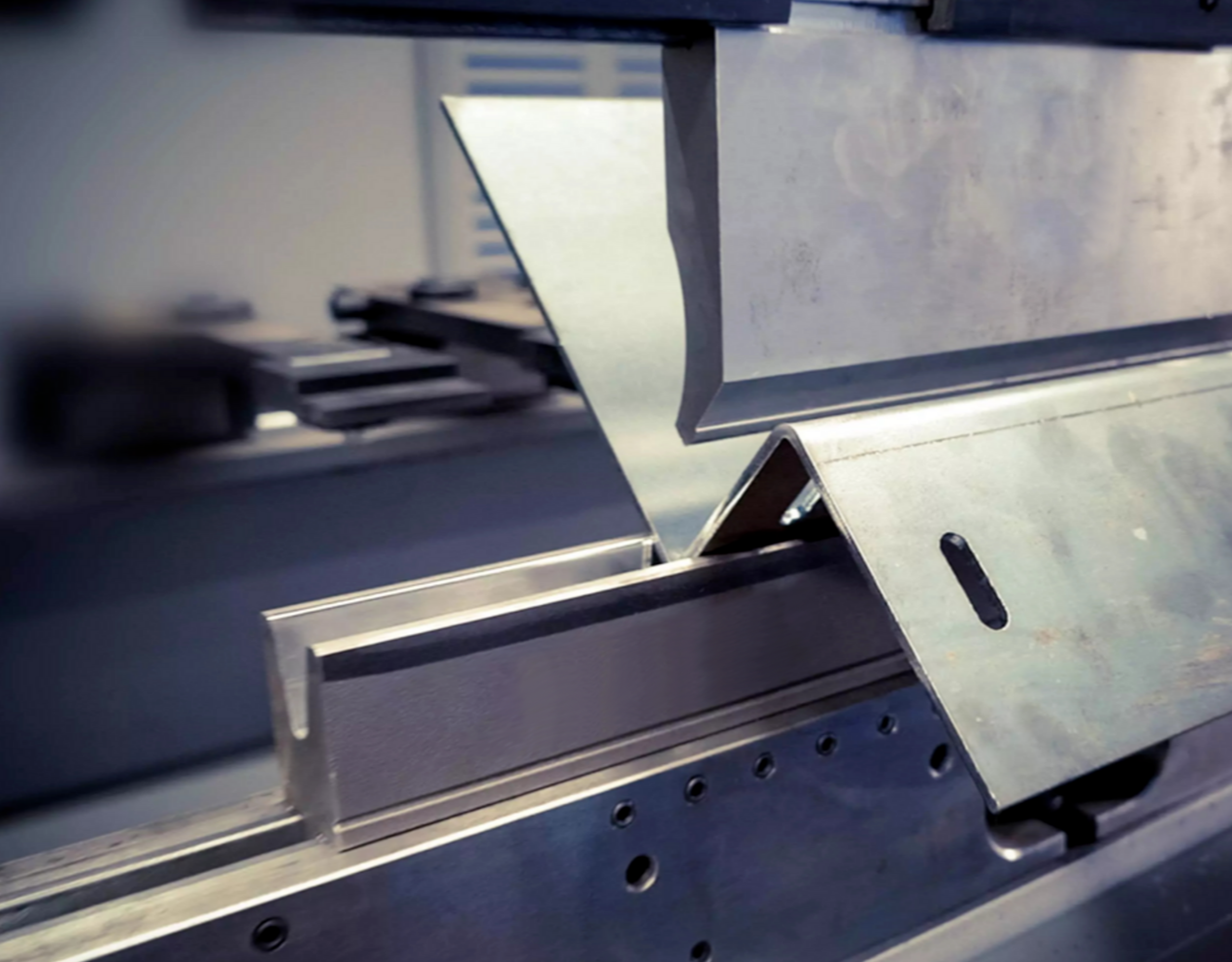

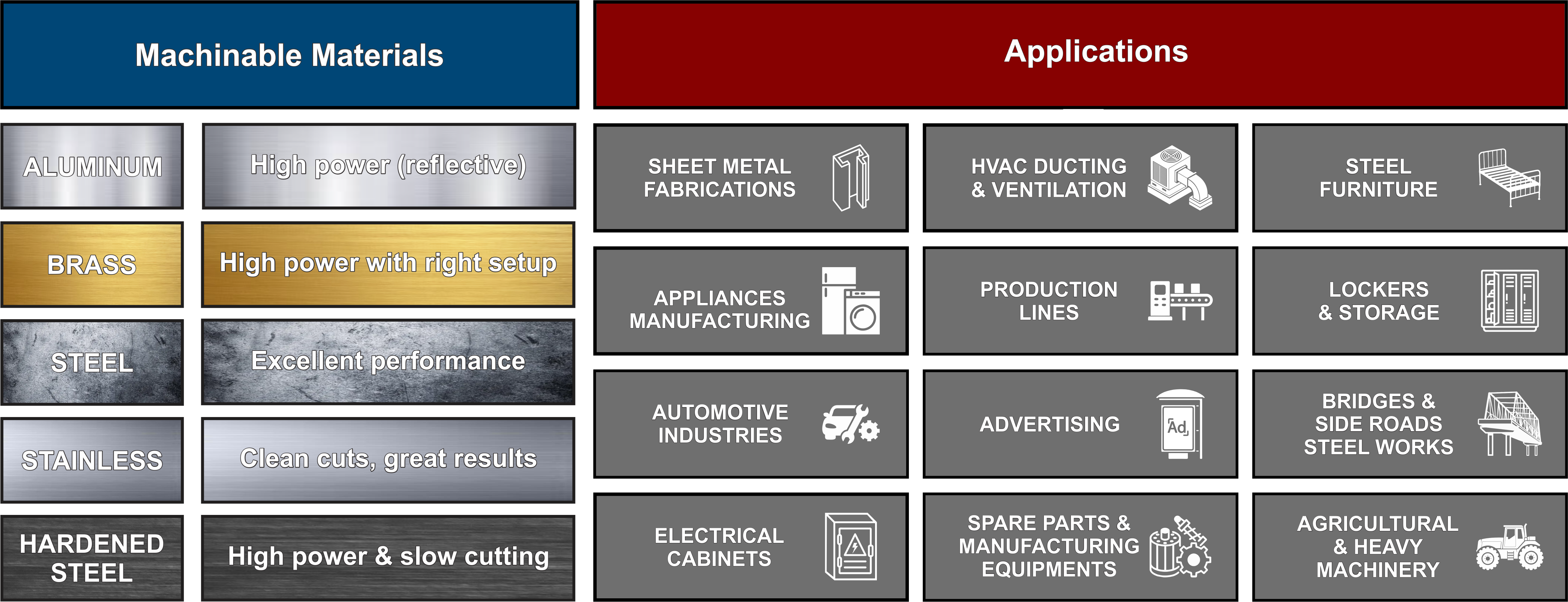

Purpose-engineered for high-accuracy sheet metal bending, our hybrid press brake combines durability, intelligence, and consistency in one package.

-

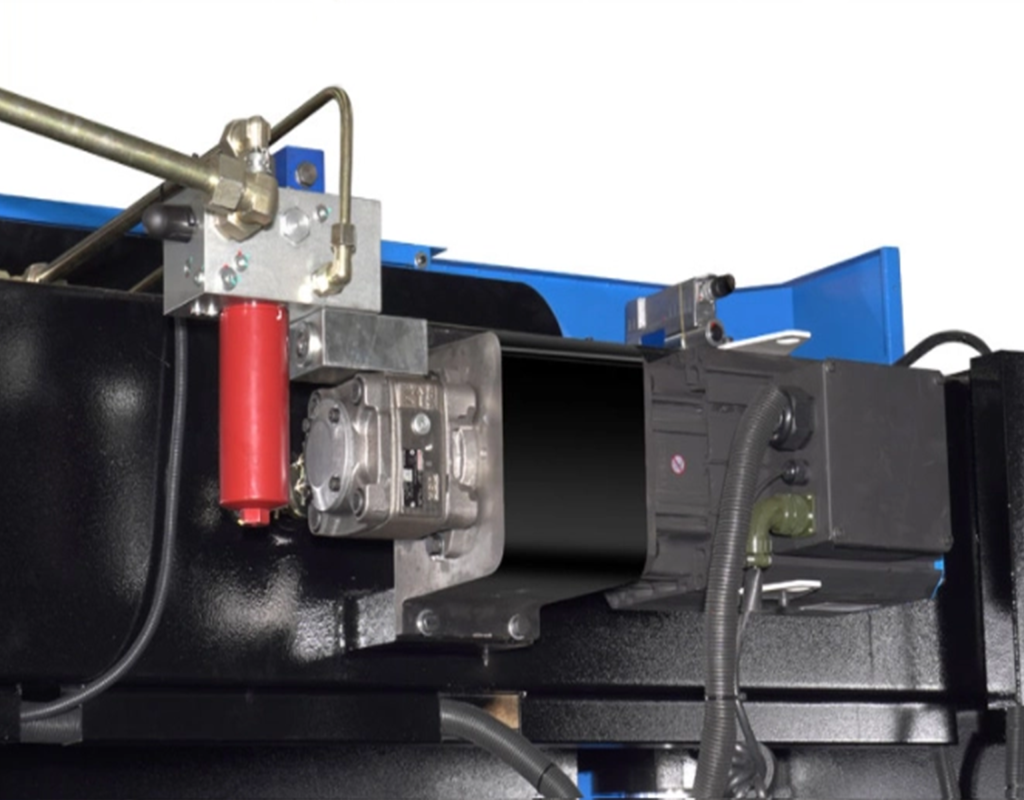

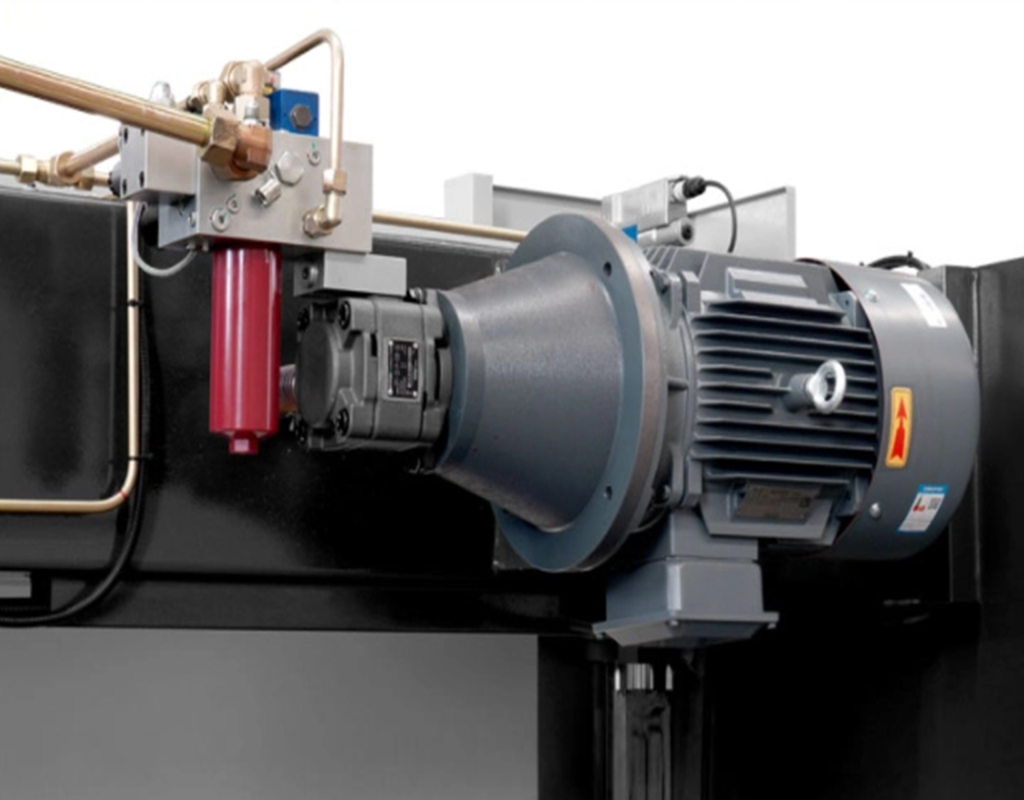

Servo-Driven Pump System

Instead of a traditional induction motor driving the pump, a servo motor is used to reduce heat, wear, and energy consumption, increasing pump lifetime while maintaining responsive power delivery. -

High-Resolution Linear Scale (Givimeasure, Italy – 5 µm Accuracy)

We integrate a Givimeasure linear scale system to monitor ram displacement in real time, enabling extremely fine control of bend angle and repeatability (±0.005 mm resolution). -

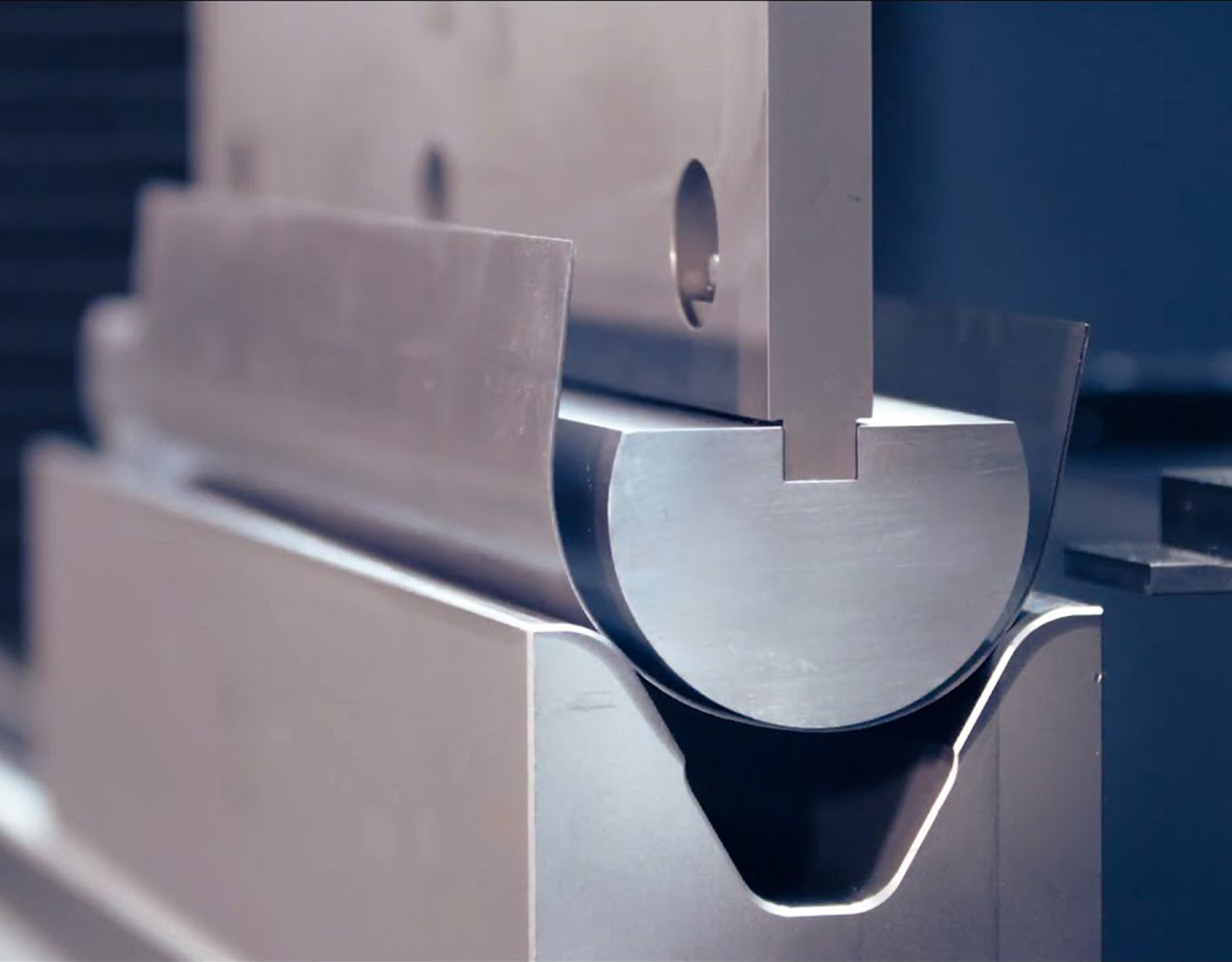

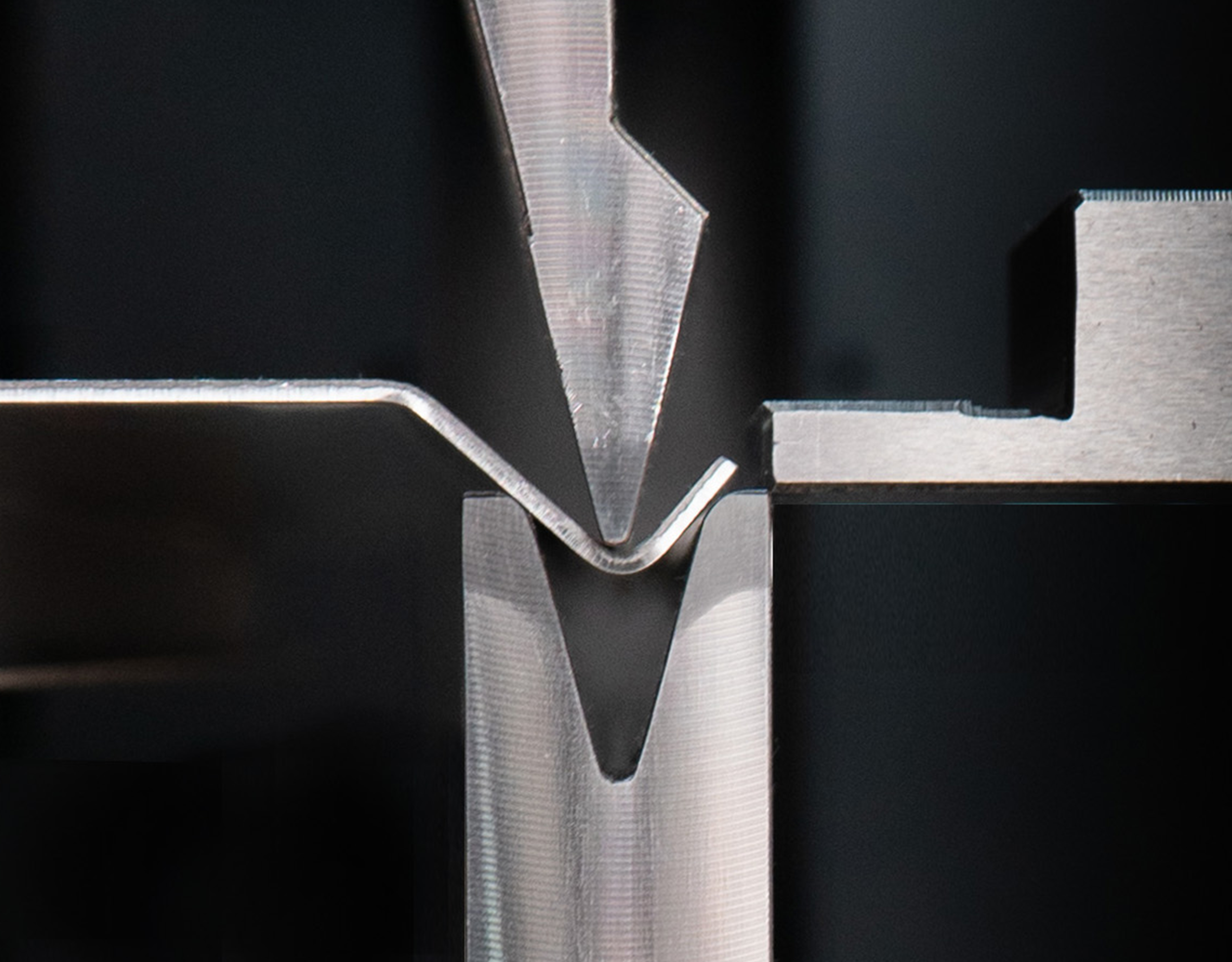

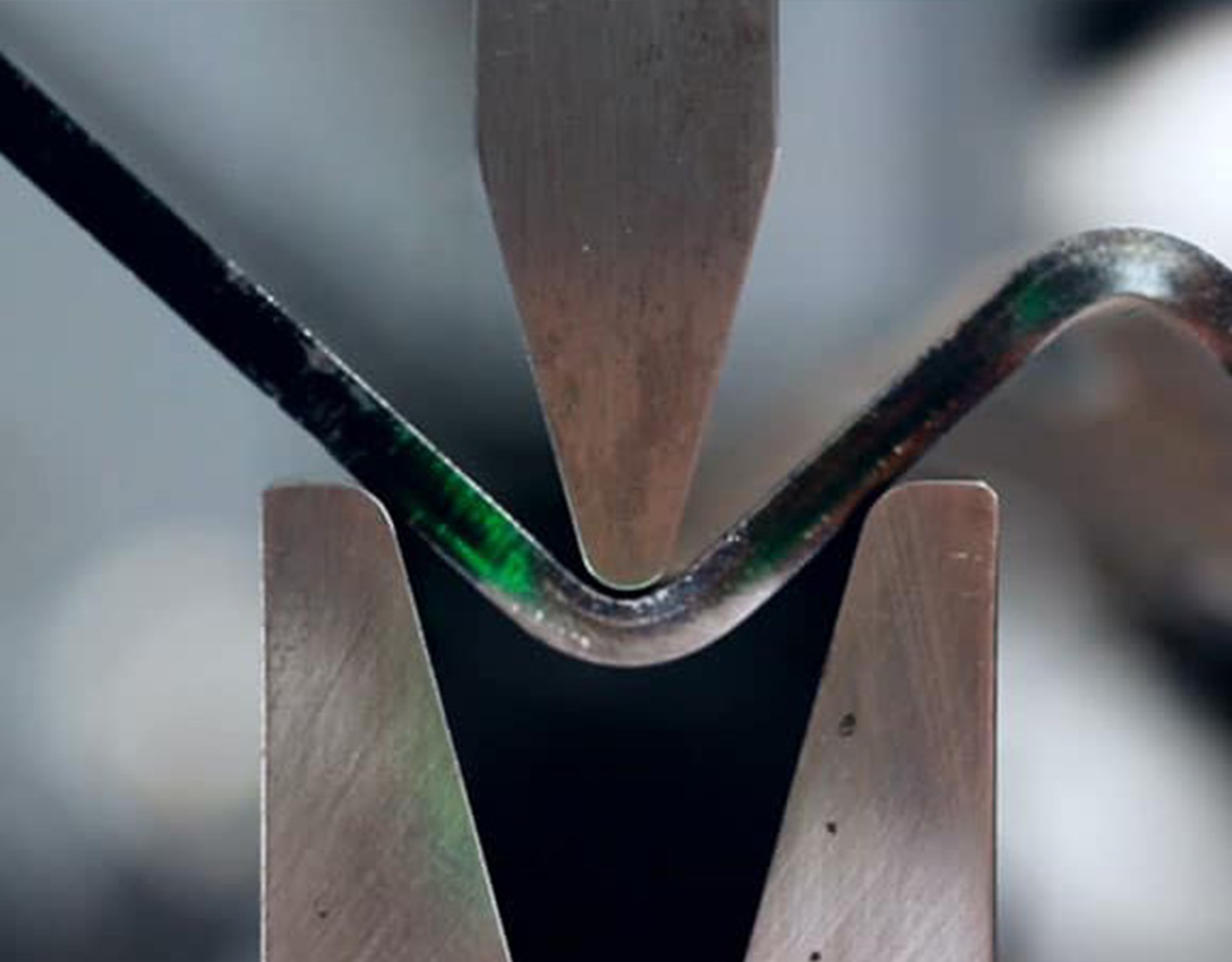

DSP Laser Angle Sensing / Crowning System

Built in laser-based angle measurement and automatic crowning compensation correct for deflection in the middle of long bending operations, ensuring uniform bend accuracy across the full bed length. -

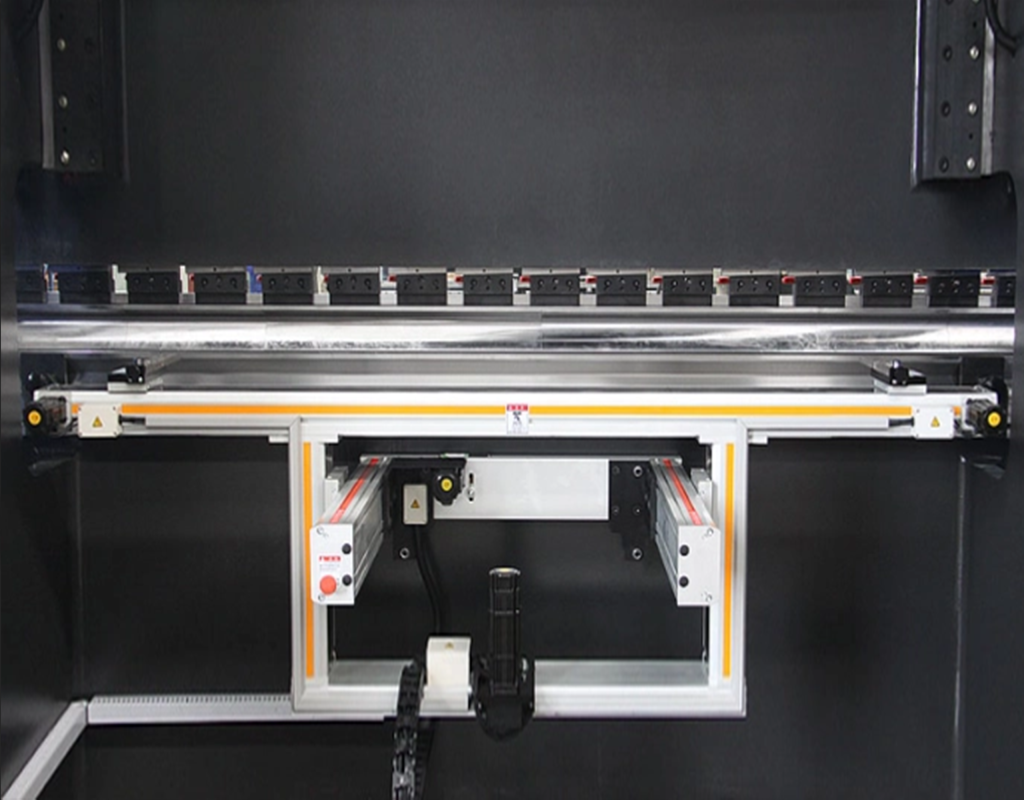

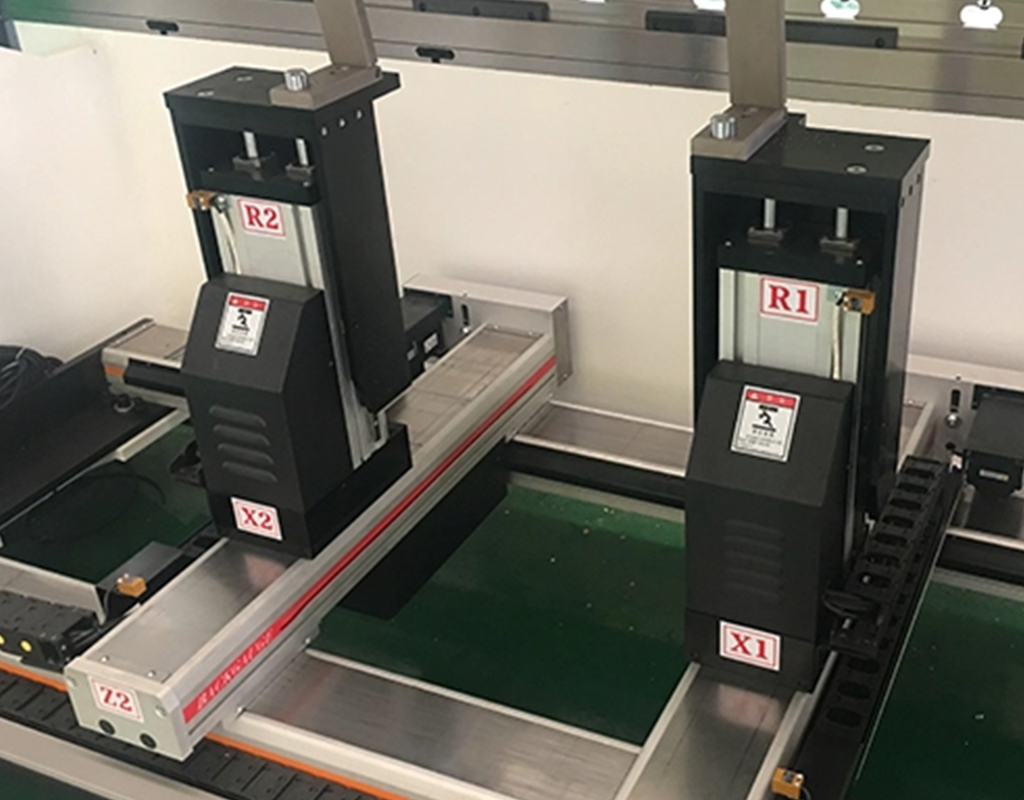

Sendo X & R-Axis Control

Multi-axis control (X for back gauge positioning and R for tool offset) gives you extra flexibility and precision in complex bending sequences. -

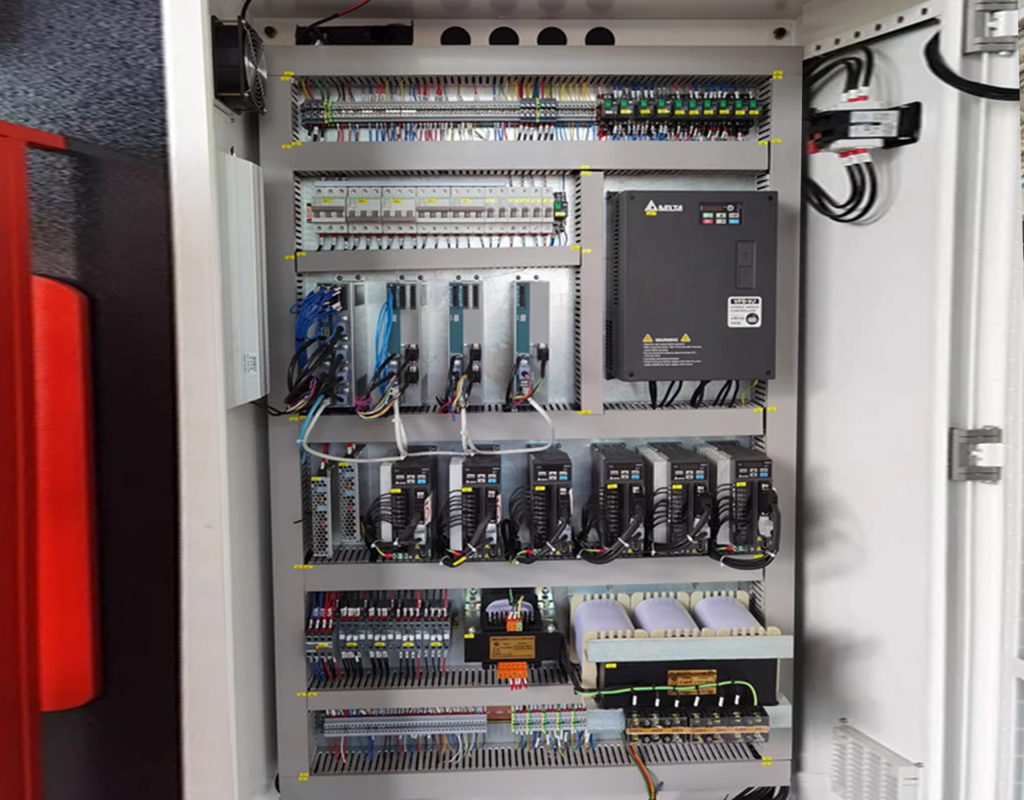

Control & Drives

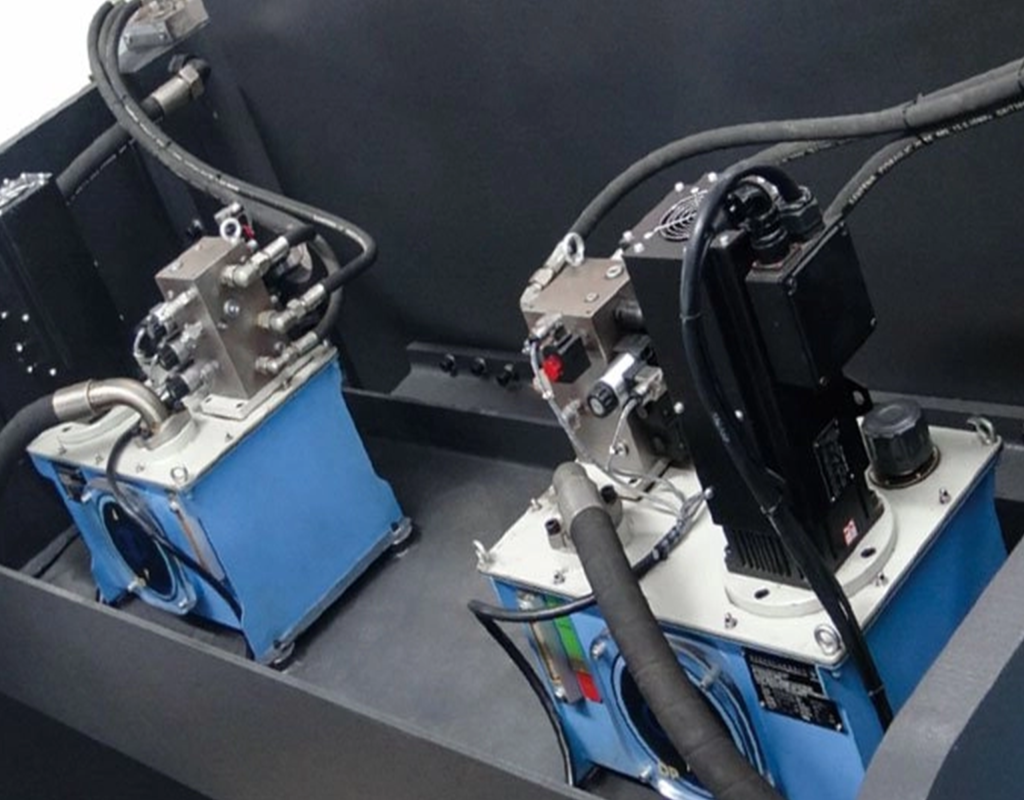

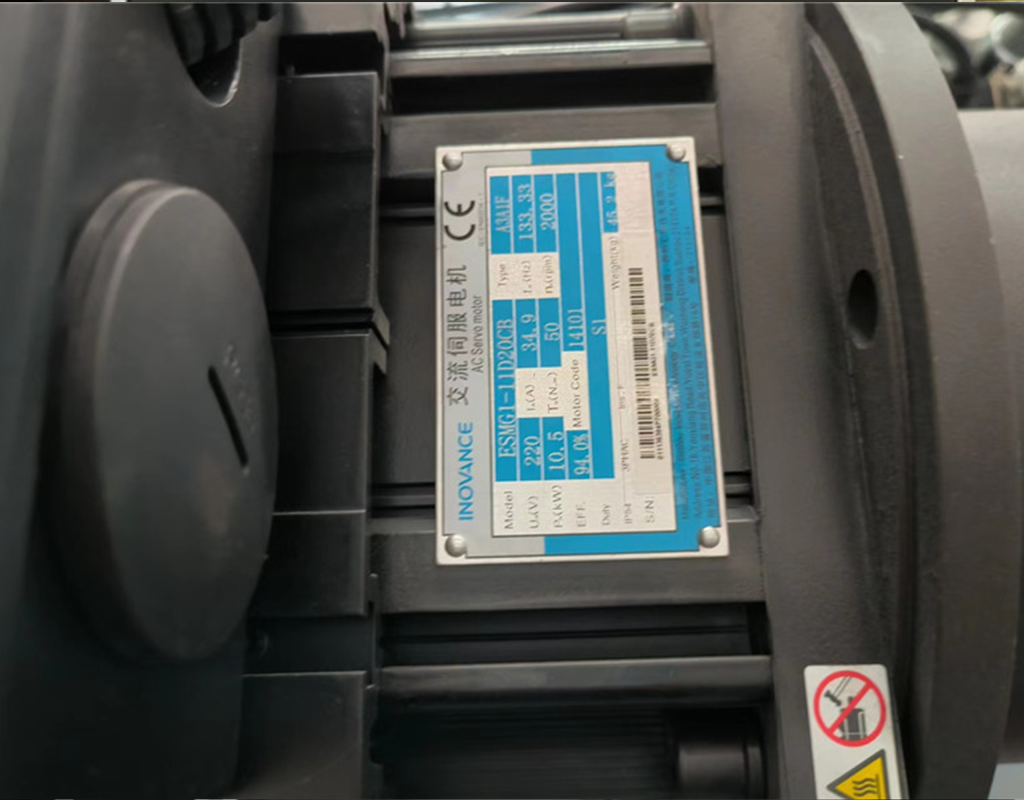

Robust Delem control with Inovance inverters; driven by Yaskawa servo motors; supported by Japanese made NOK sealed pistons to prevent oil leakage and extend hydraulic system life. -

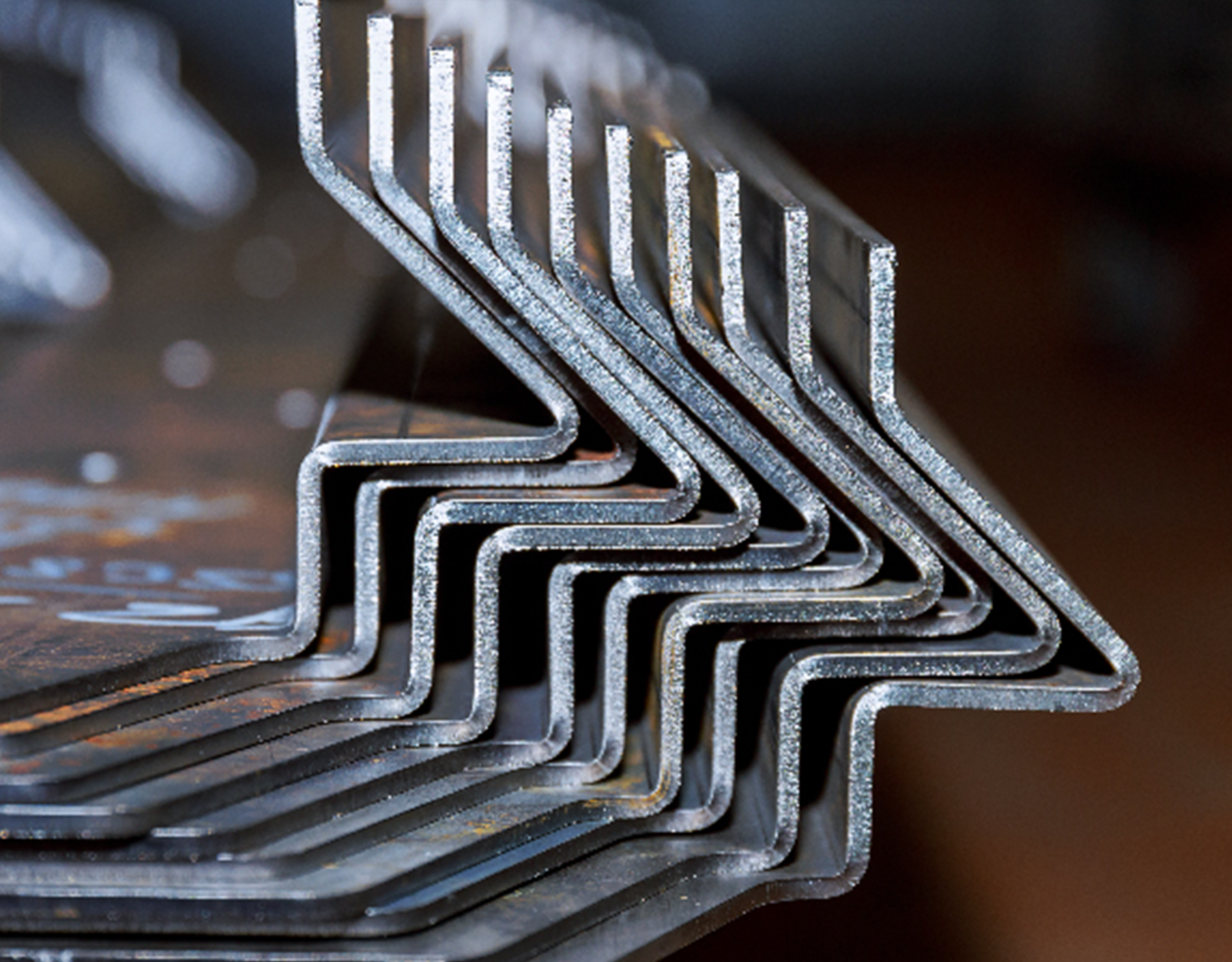

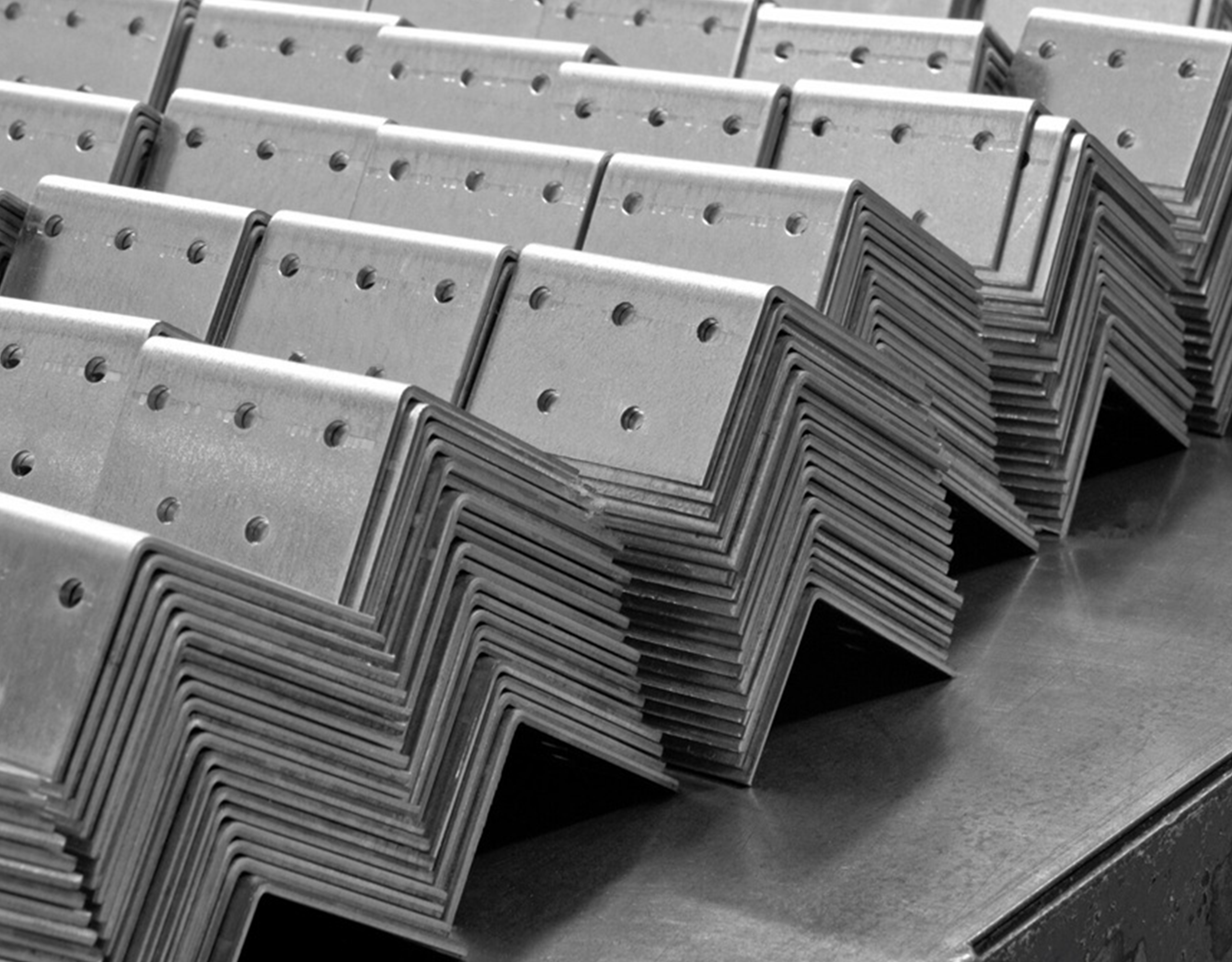

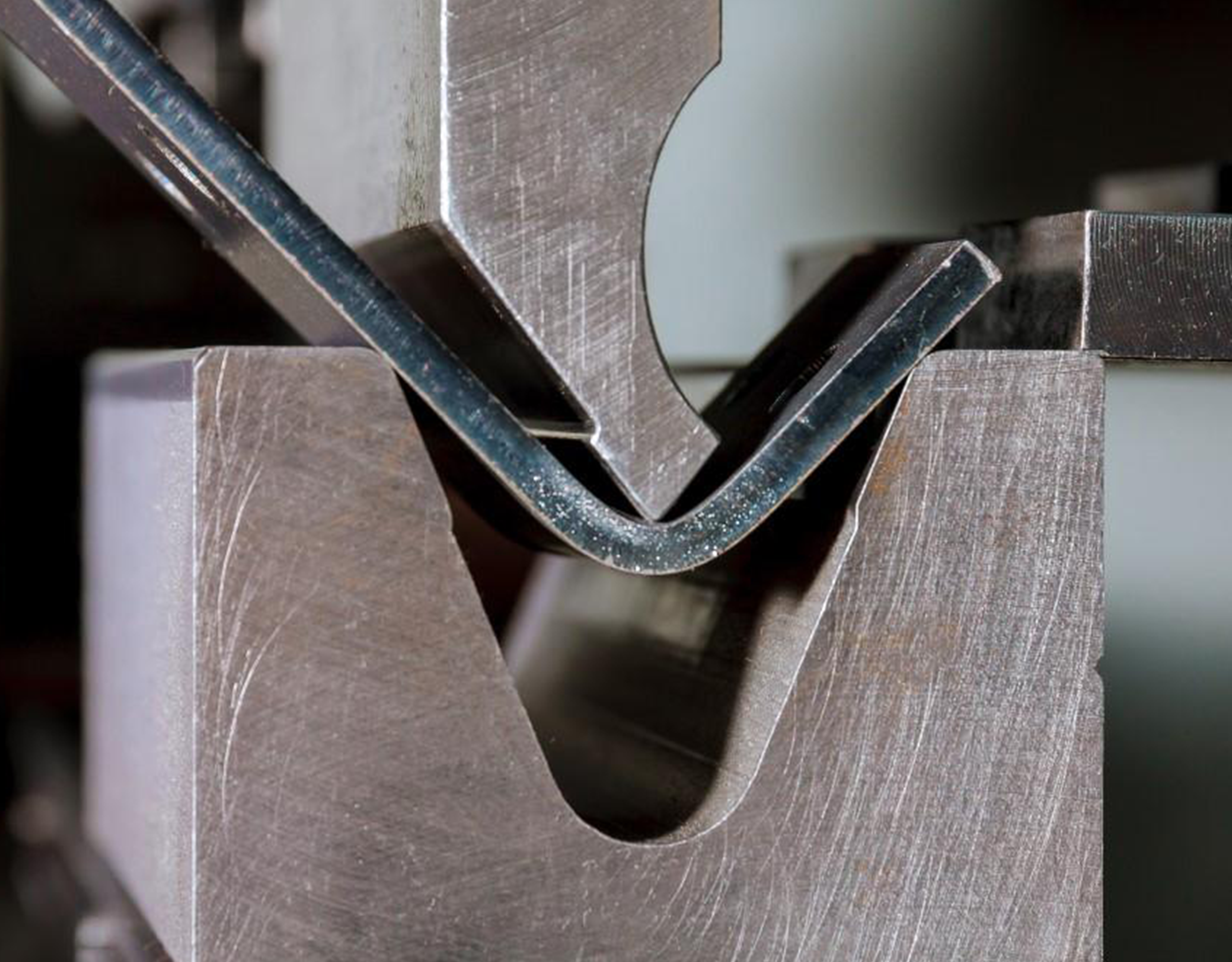

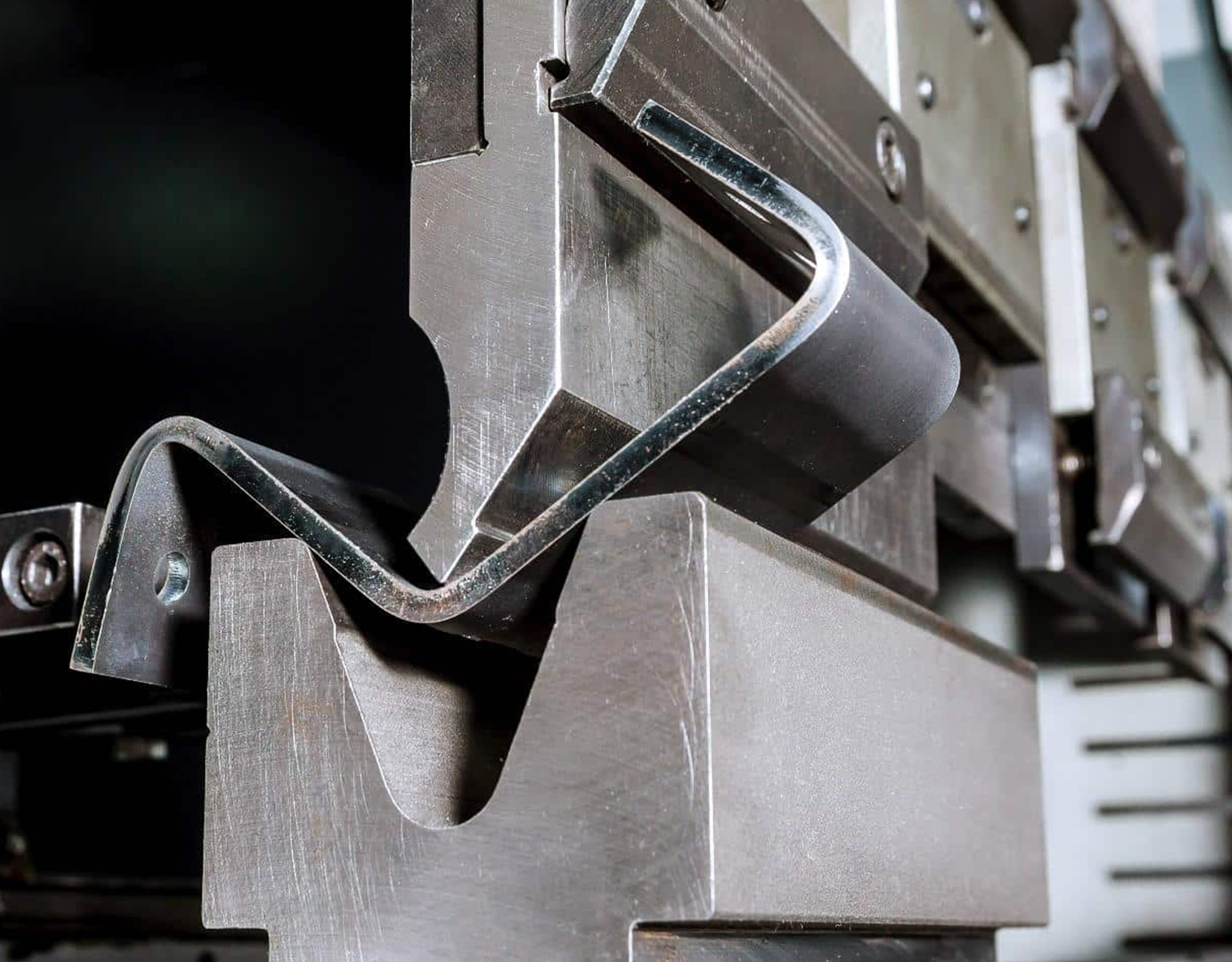

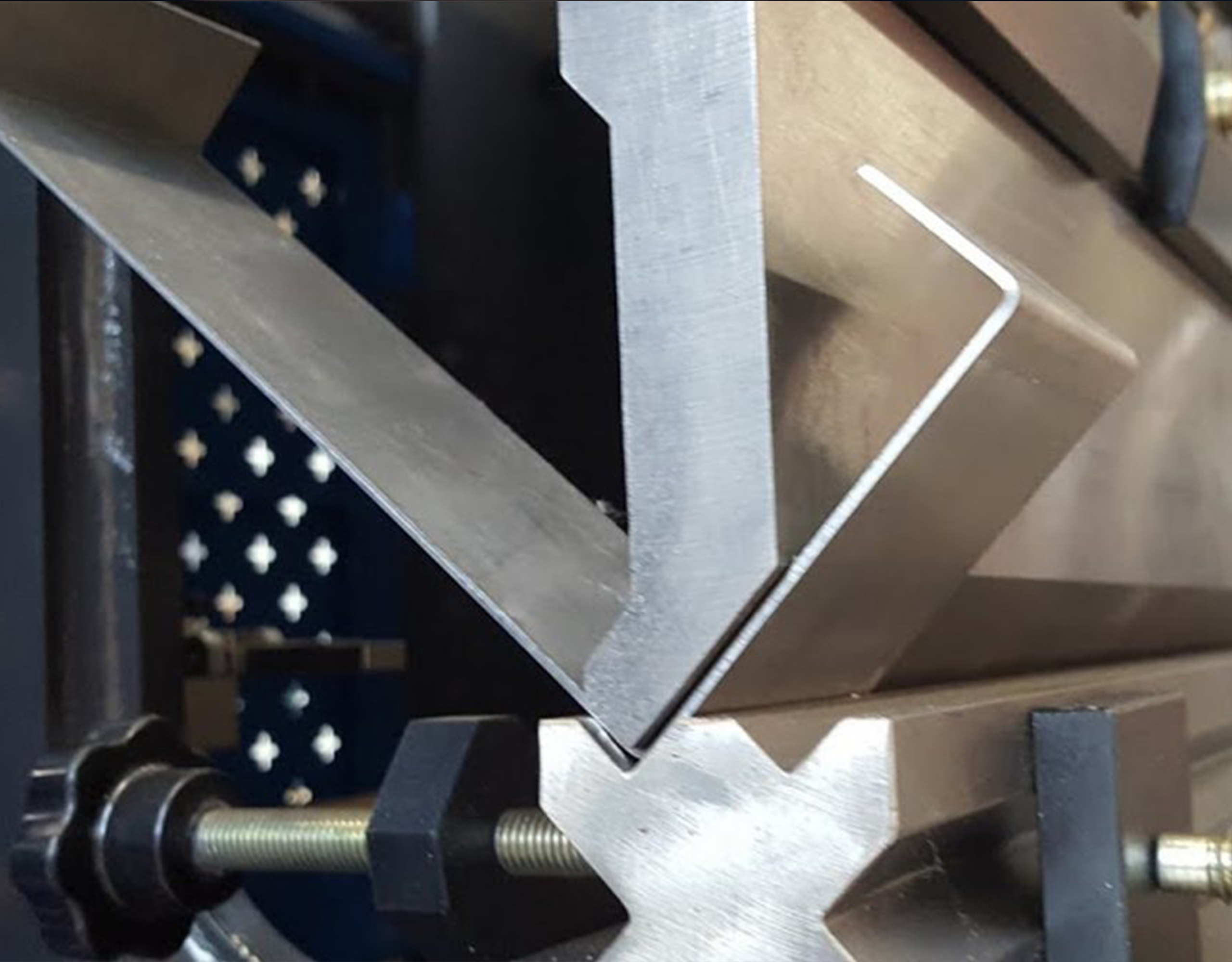

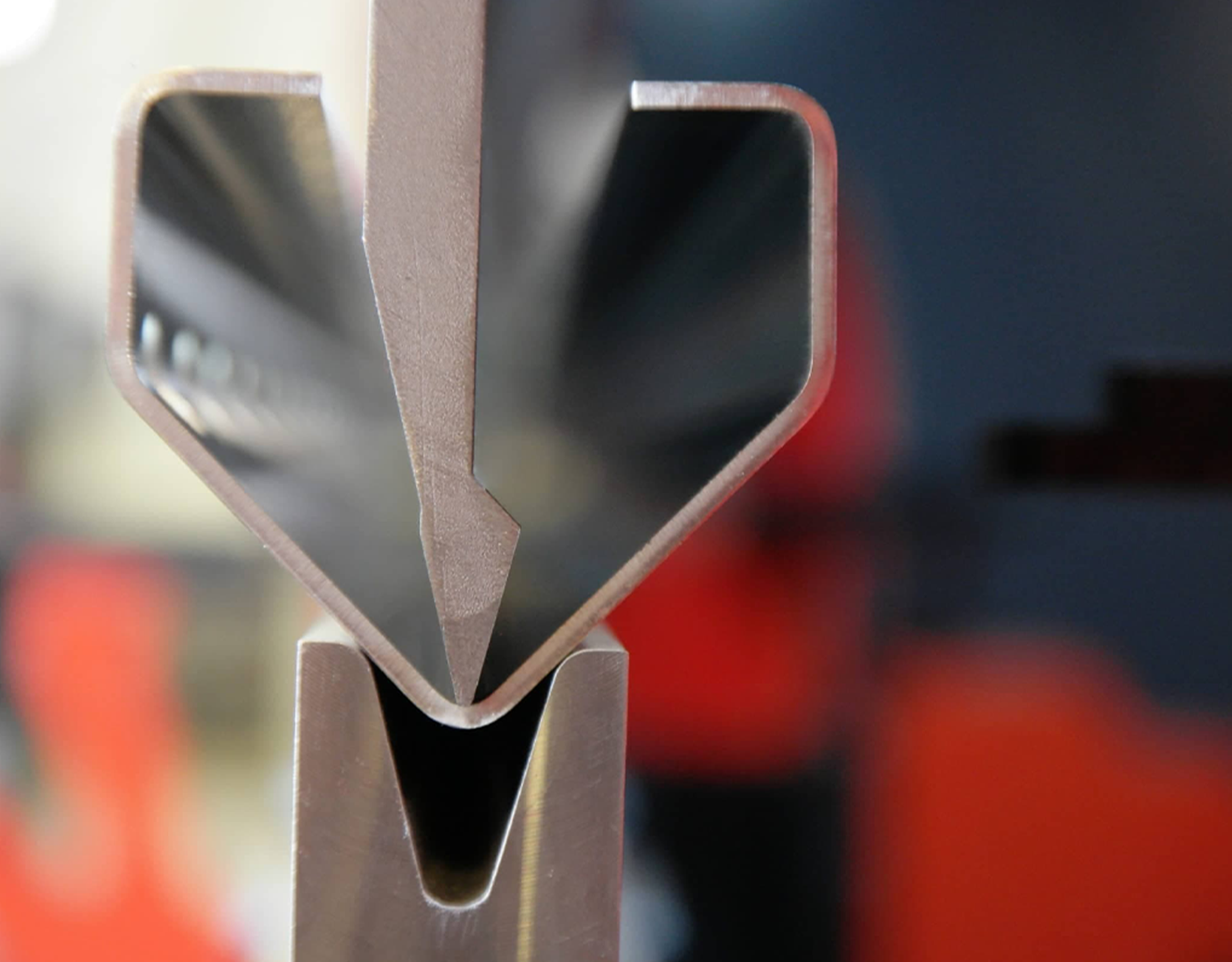

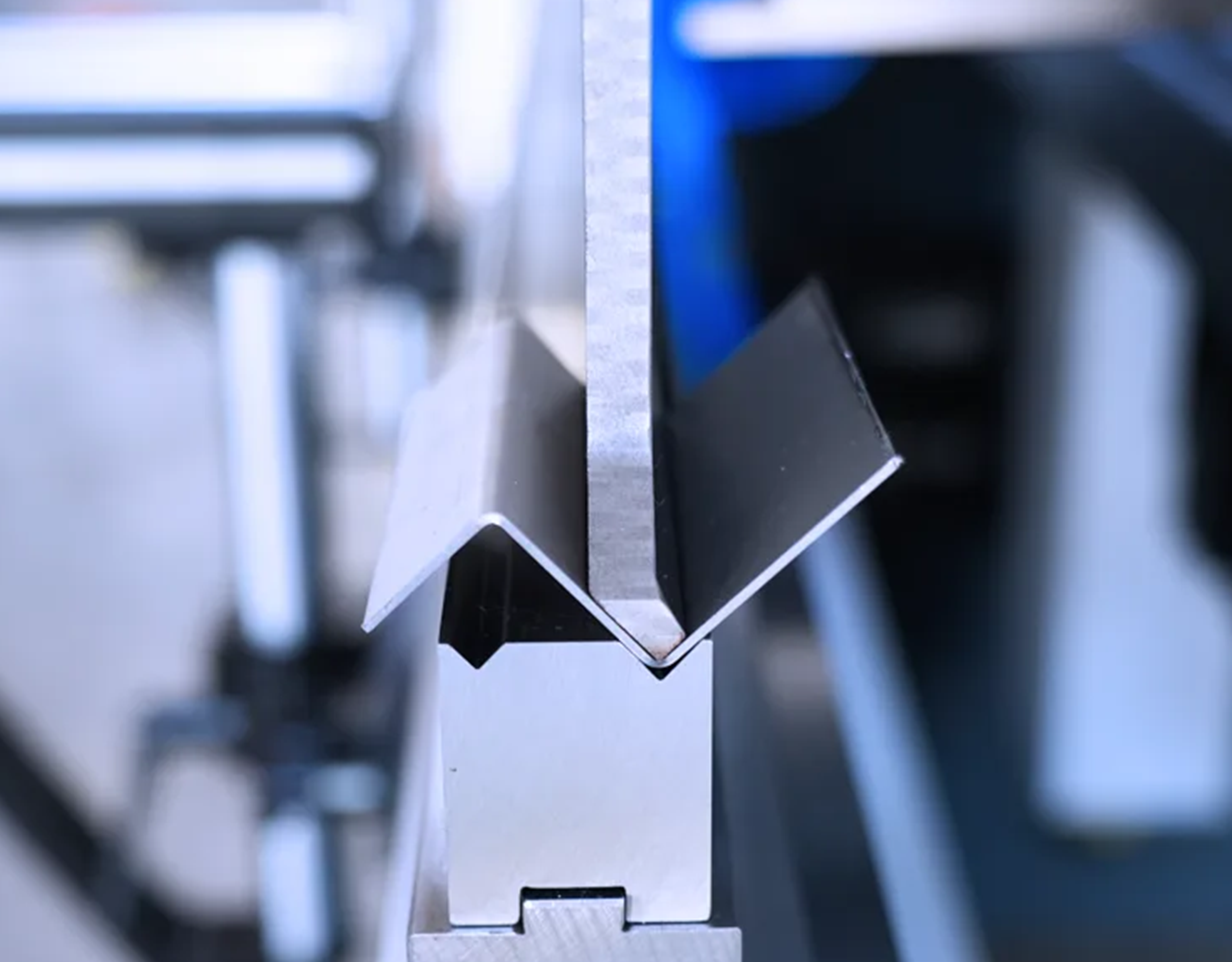

Tooling, Punchs & Dies

Full tool & punch mold availability for an extensive range of bend profiles.

CNC PRESS BRAKE MACHINE

SPECIFICATIONS

|

Table length range

|

1,300 – 10,000 mm

|

Controller

|

Delem – Netherlands

|

|

|

Nominal pressure range

|

500 – 8,000 kN

|

Electric components

|

Schneider – France

|

|

|

Distance between columns

|

1,120 – 7,800 mm

|

Motors

|

Siemens – Germany Inovance – China

|

|

|

Throat depth range

|

250 – 600 mm

|

Gear pump

|

Sunny – USA

|

|

|

Stroke range

|

150 – 320 mm

|

Seal ring

|

NOK – Japan

|

|

|

Open height range

|

460 – 800 mm

|

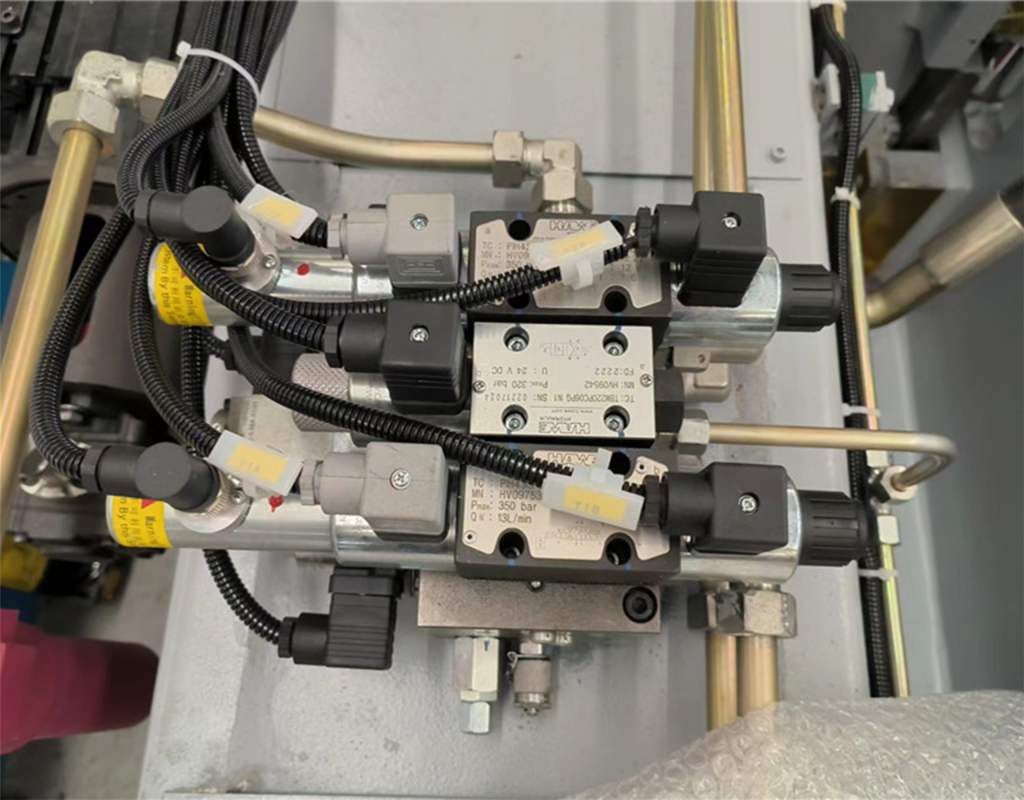

Hydraulic system

|

Bosch/Rexroth – German

|

|

|

Main motor power range

|

(5.5×1) – (30×2) kW

|

Ball screws & liner guides

|

HIWIN – Taiwan

|

|

|

Precision

|

5 µm

|

Grating ruler

|

GIVI – Italy

|

|

|

Laser optical safety guards

|

MSD Laser

|

Tubing connector

|

EMB – Germany

|

|

|

Angle measuring system

|

Alfa-F

|

Back-gauge servo motor and drive

|

Delta – Taiwan

|

|

|

Power requirements

|

380V / 50 Hz adjustable

|

Standard accessories

|

Grease gun / foot switch

|

|

EMAR reserves the right to make changes to technical specs without prior notice